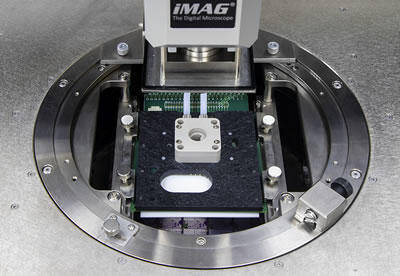

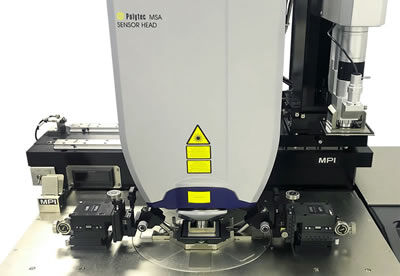

MPI Laser Cutter System LCS-635

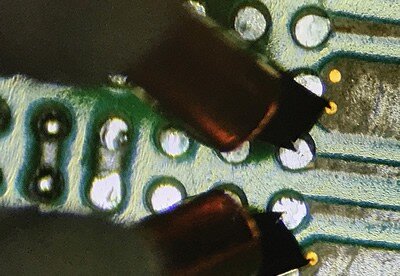

The unique MPI Laser Cutter System LCS-635 is designed for accurate and reliable Failure Analysis and Design Validation applications. Variable configurations based on 1064 nm, 532 nm, 355 nm or 266 nm wavelengths provides the capability to remove several semiconductor materials and metals selectively, see below the table.

Features & Benefits

High Beam Quality – Low Energy Consumption

The MPI Laser Cutter System is based on compact Diode Pump Solid State Laser, providing high beam quality, even at 266 nm, with enhanced pulse-to-pulse stability, and these by the unsurpassed low energy consumption.

Long Lifetime – Low Maintenance

The LCS-635 has more than 150x times longer lifetime as other conventional available laser systems on the market, and the passive, conductive laser head cooling, which eliminates the need for water, are making the system very reliable and reducing significantly the maintenance costs.

Wavelength – Application Matrix

| LCD Materials | Chromium Color Filter (Red / Green) | Chromium Color Filter (Blue / Green) | (Blue / Green) |

| Semiconductor Materials | Nitride Polyimide (big cuts) SOG Poly-silicon | Polyimide | |

| Metals | Aluminum Tungsten | Aluminum Tungsten | Aluminum |