MPI TS150, TS200 & TS300

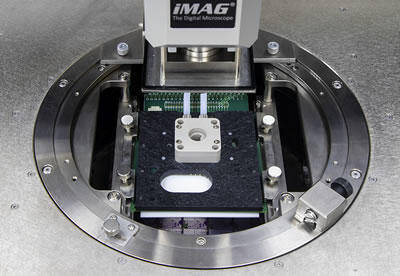

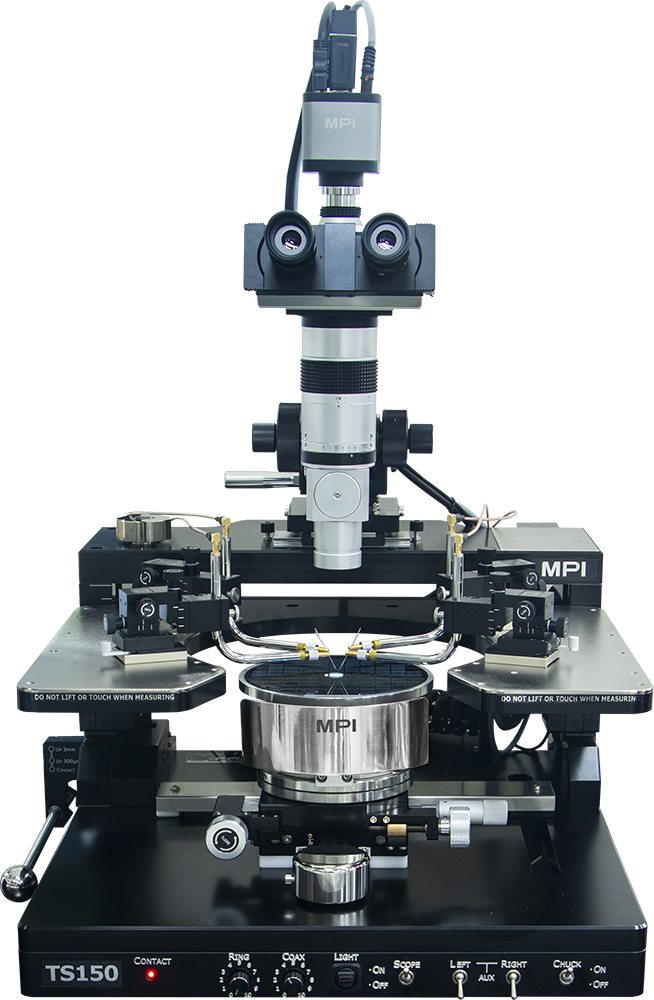

MPI TS150 - 150 mm Manual Probe System

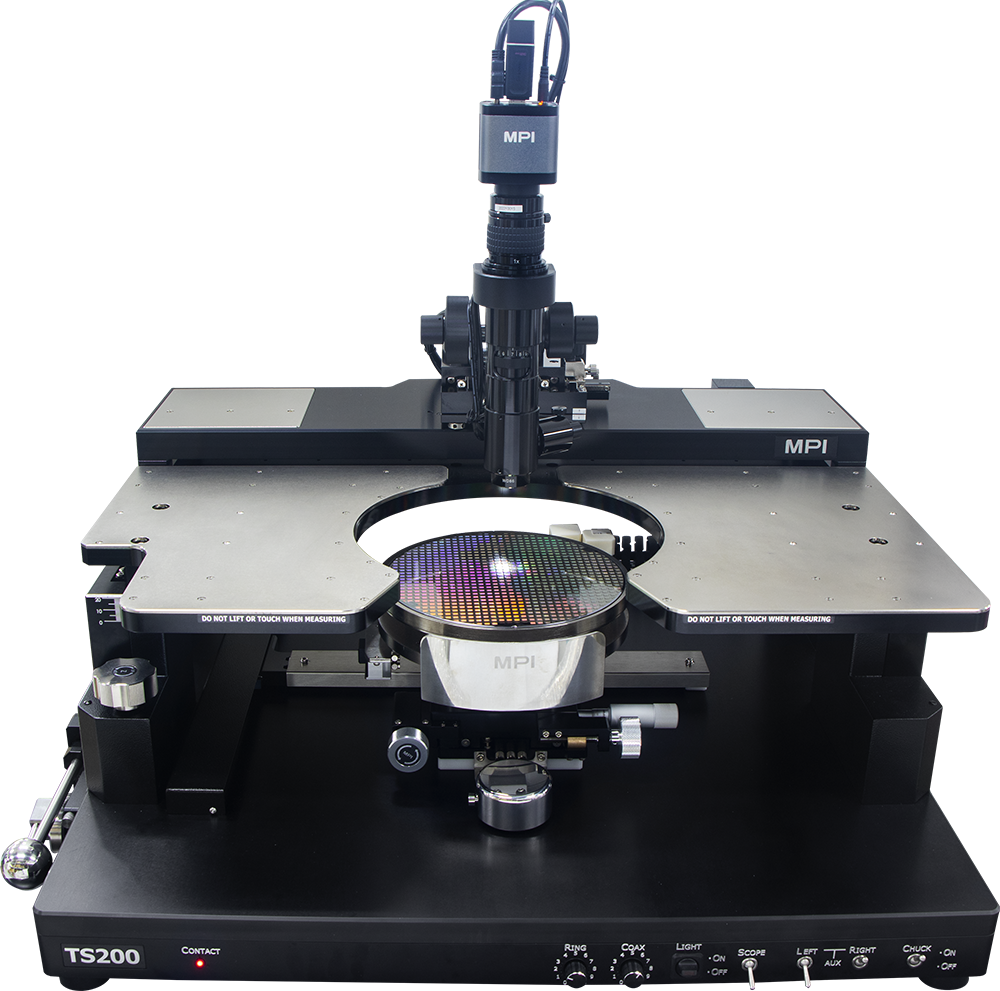

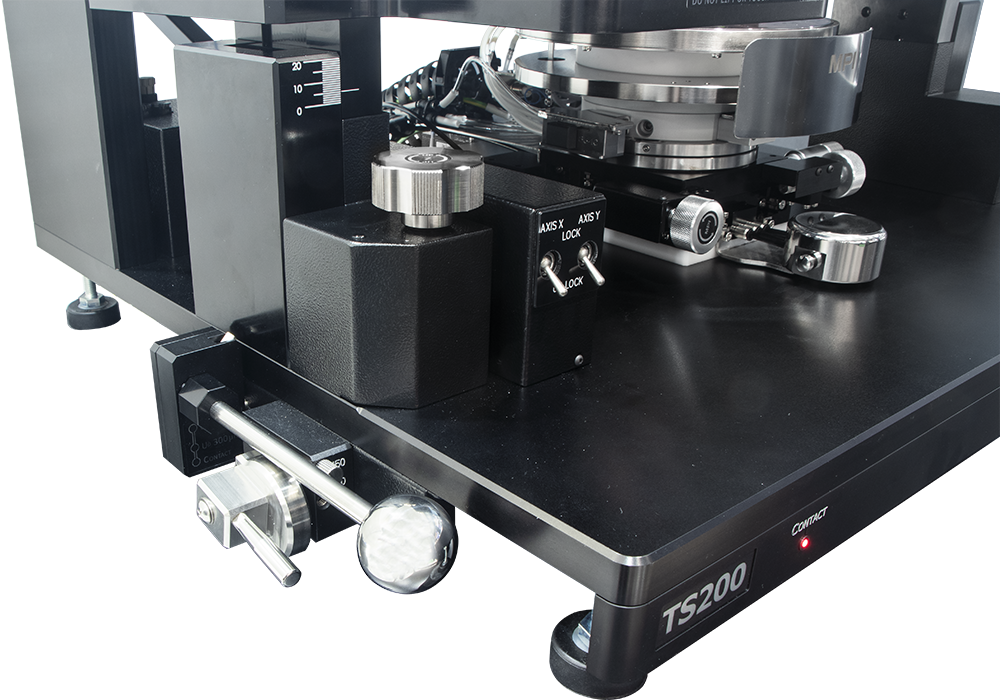

MPI TS200 - 200 mm Manual Probe System

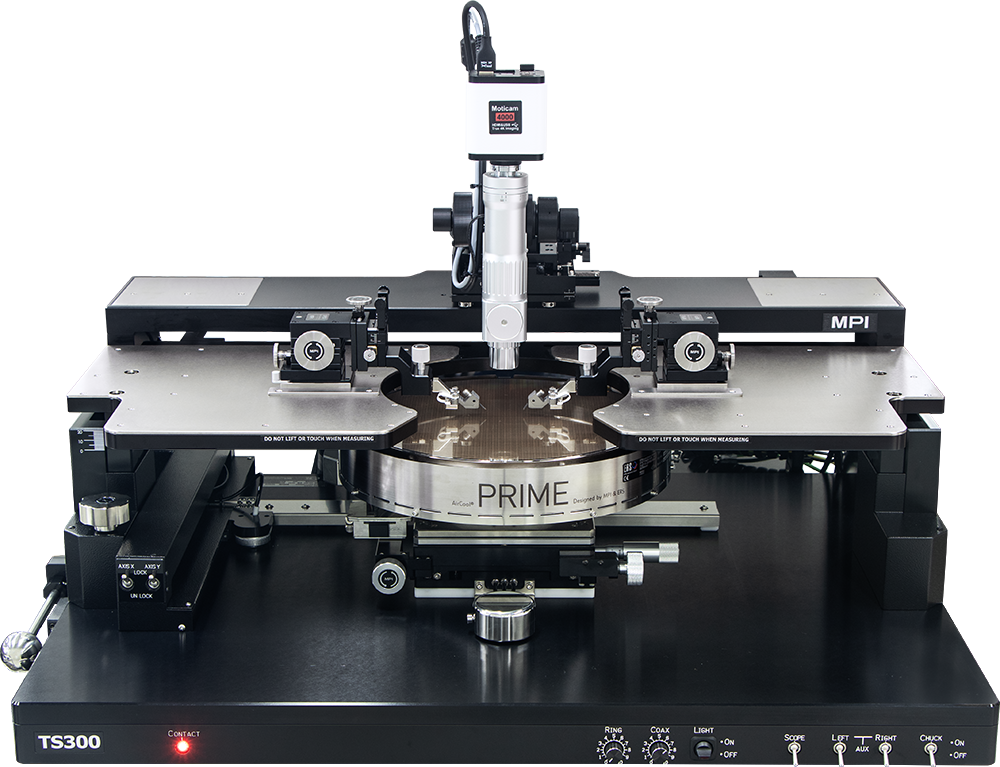

MPI TS300 - 300 mm Manual Probe System

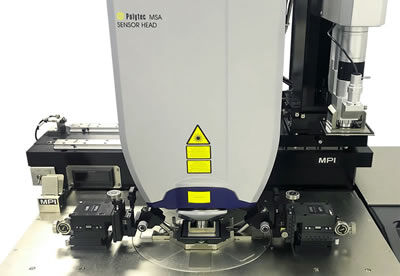

MPI TS200 with Polytec MSA600 Motion System Analyzer

MPI TS150, TS200 & TS300 probe stations are rich on exciting features, making the daily operation easy, intuitive, and convenient by ensuring highly accurate measurements.

![]() TS150 Fact Sheet

TS150 Fact Sheet ![]() TS150 Data Sheet

TS150 Data Sheet

MPI TS150, TS200 & TS300 probe stations are rich on exciting features, making the daily operation easy, intuitive, and convenient by ensuring highly accurate measurements.

Features & Benefits

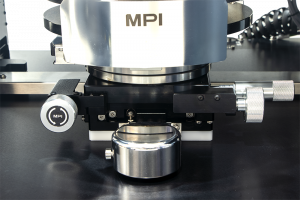

Air-Bearing Stage

The MPI unique air-bearing stage design, with simple single-handed puck control, provided unsurpassed convenience of operation for fast XY navigation and quick wafer loading without compromising accurate and fine positioning capability with the additional fine and accurate 25×25 mm XY-Theta micrometer movement.

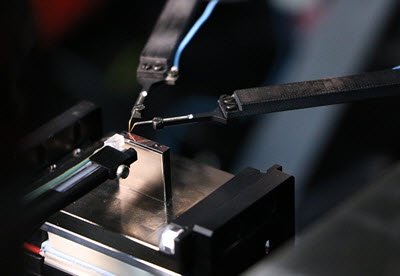

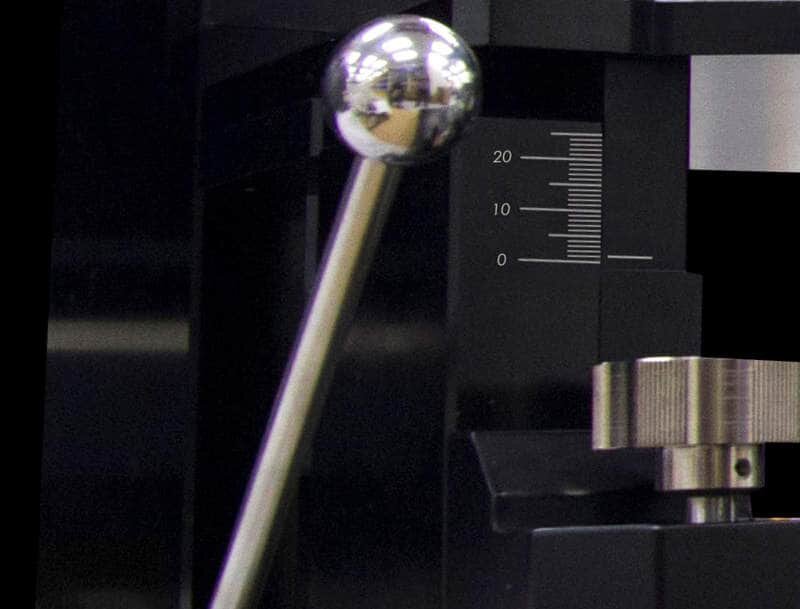

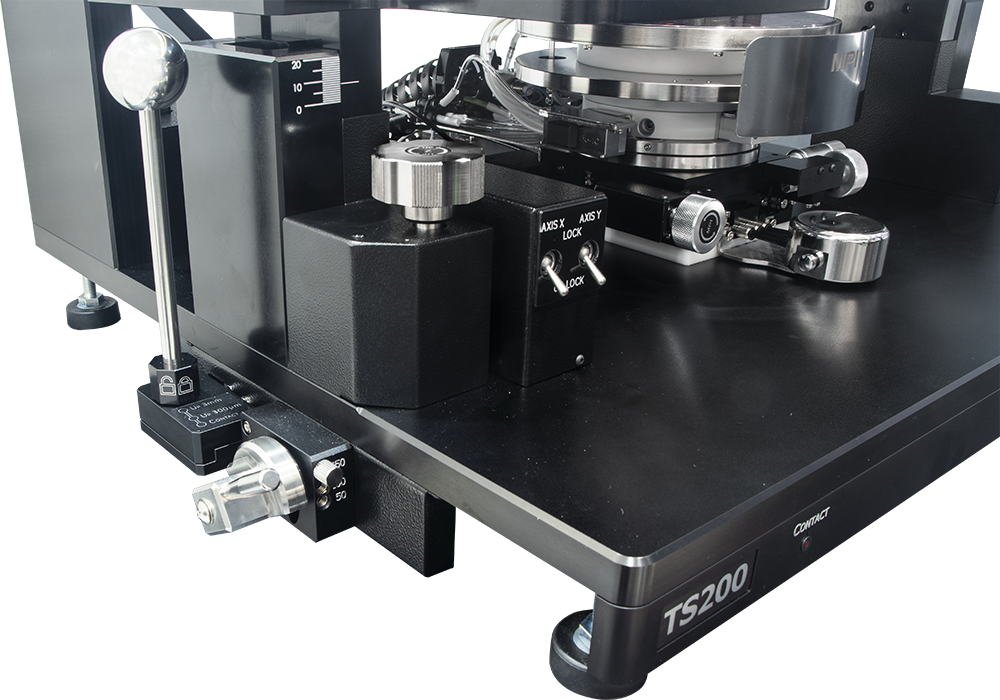

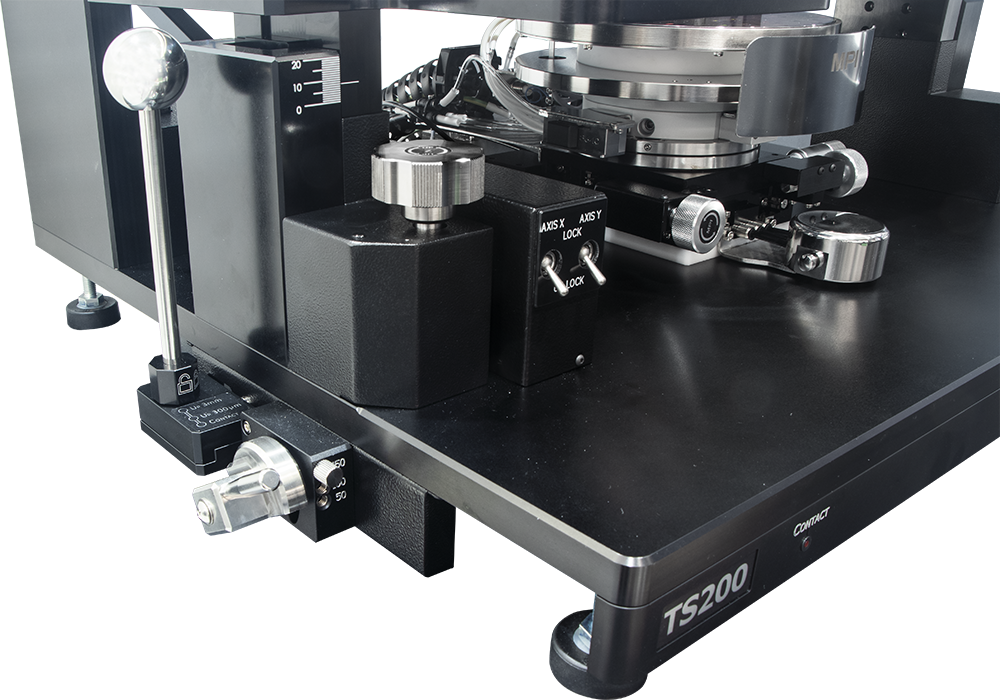

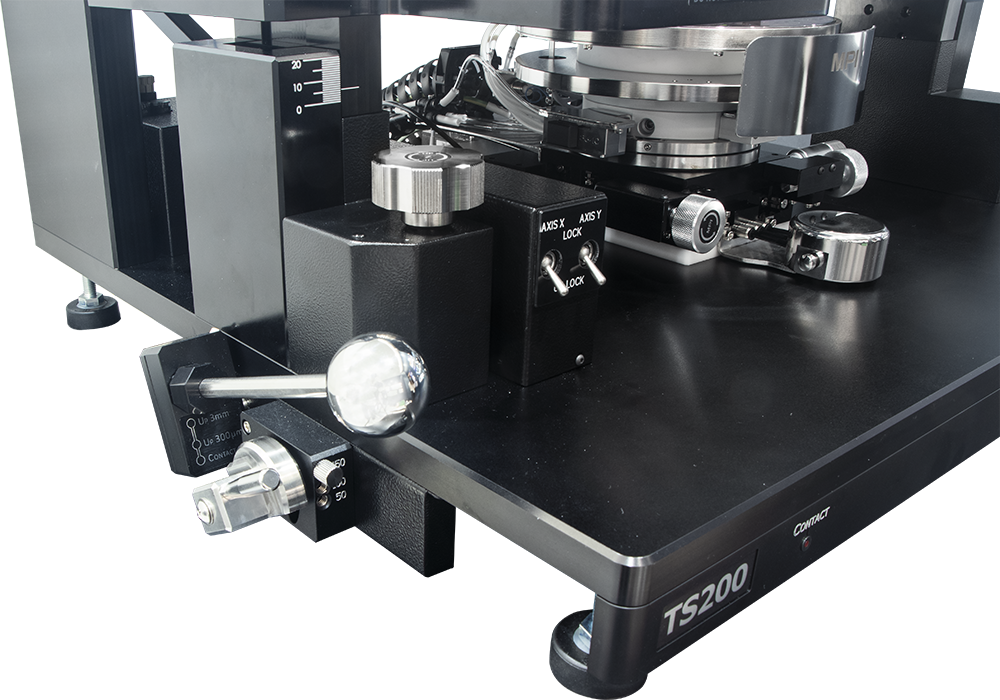

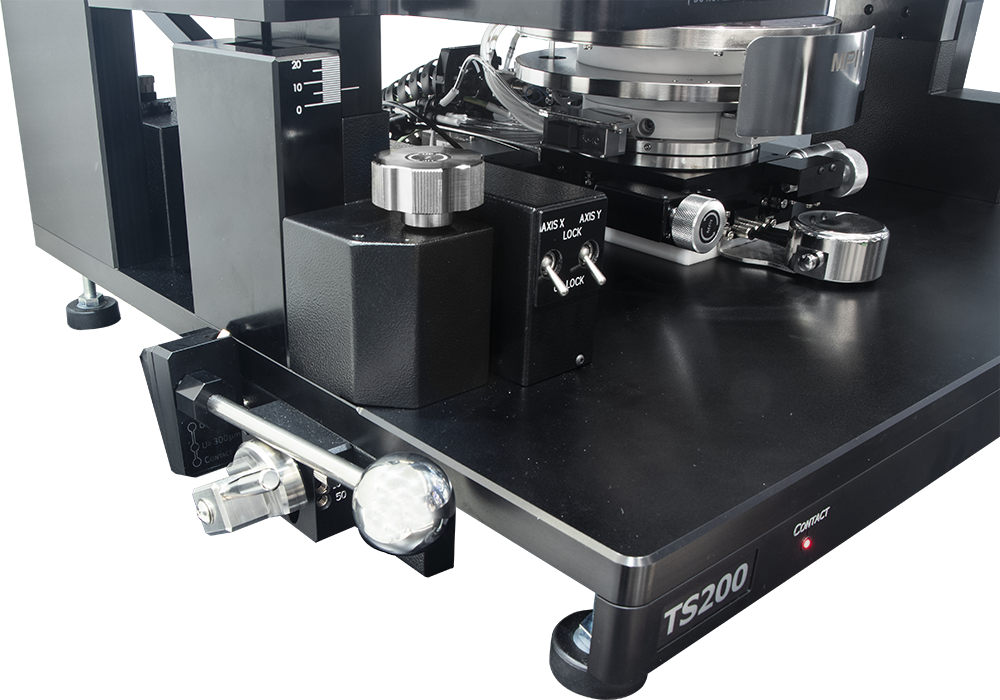

Unique Platen Lift

with Probe Hover Control™

Measurement accuracy depends on the contact quality first! The highly repeatable (1µm) platen lift design with three discrete positions for contact, separation (300µm), and loading (3mm) with a safety lock utility are all examples of unparalleled functionality incorporated into MPI manual probe systems. These features prevent unexpected probe or wafer damage while providing intuitive control and accurate contact positioning. This capability is especially critical in both high frequency and high power applications in order to achieve the most accurate measurement results.

For TS200 and TS300, additional Probe Hover Control™ comes with hover heights (50, 100 or 150 µm) for easy and convenient probe to pad alignment.

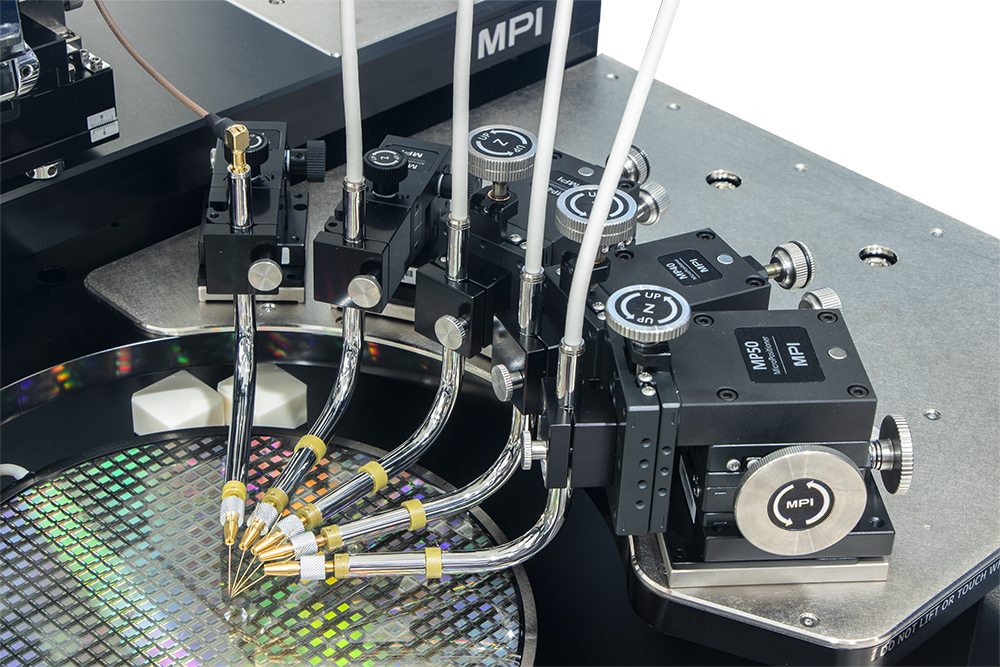

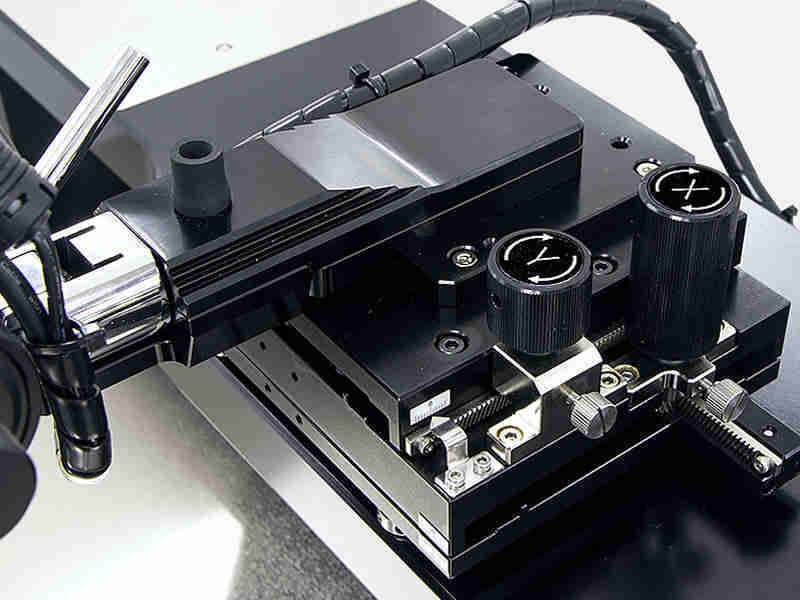

Compact and Rigid Platen Design

The compact and rigid platen design accommodates up to ten DC or four RF MicroPositioners for various application requirements.

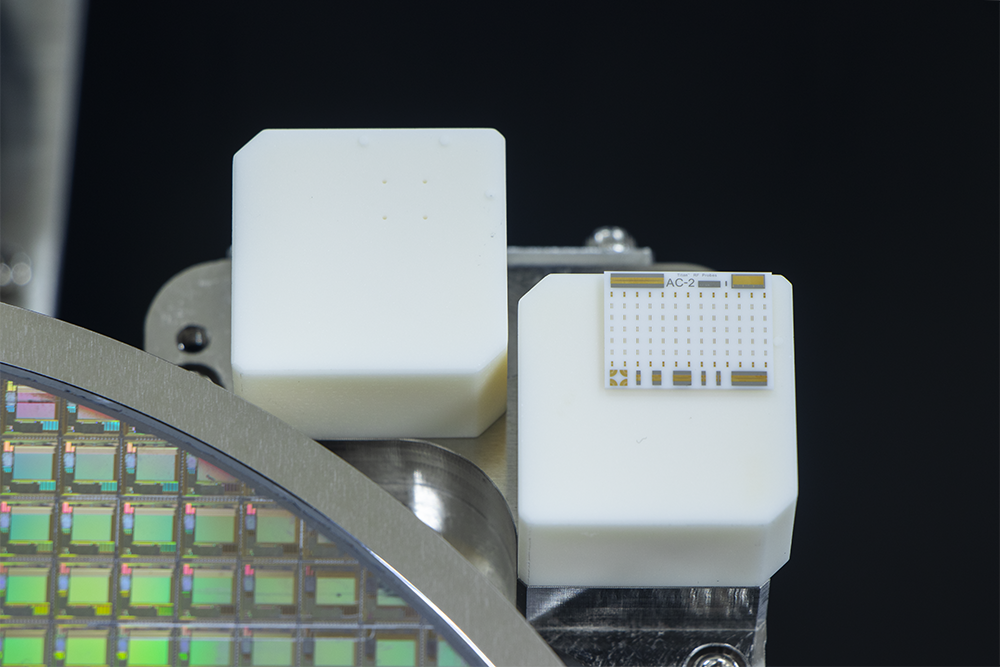

Various Chuck Options

The manual systems are available with various chuck options to meet different budgets and application requirements. Chuck options include MPI’s coaxial or triaxial Chucks or various ERS thermal chucks to support temperature measurement up to 300 °C – as example for seamless integration of the thermal touch controller for quick and convenient access and operation.

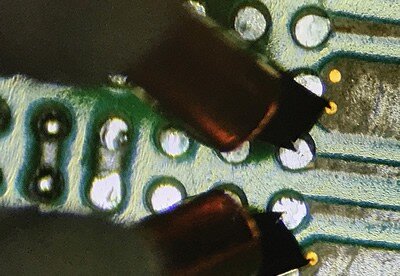

Optic Tilting

90 degree tilting as a standard feature or even pneumatically driven, linear Z lift offers very convenient set-up and easy probe tips replacement.

Vibration Isolation Platform

All manual systems includes vibration absorbing base to achieve stable and reliable long-term probe to pad contact which ensures reliable measurement results. Vibration isolation platform or table are optional available where the laboratory environment requires extensive vibration protection.

MPI TS150, TS200 & TS300 Probe Systems

are open, easy to use and cost effective manual probe systems designed for precision analysis of substrates and wafers up to 150, 200 and 300mm. These systems address a wide variety of applications such as Failure Analysis, Design Validation/IC Engineering, Wafer Level Reliability, MEMS, High Power and Device Characterization and Modeling.