TS2000-HP – Advanced High Power Solution

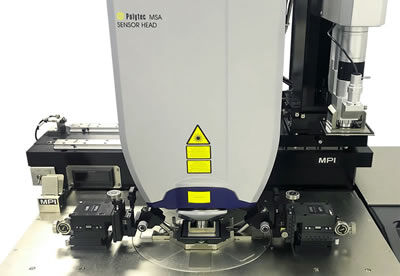

MPI’s automated TS2000-HP provides reliable on-wafer high power device measurement over wide-temperature range and measurement capability up to 3 kV (triax) / 10 kV (coax) and 600 A (pulsed). Advanced ShielDEnvironment™ offers low-noise and shielded test environment.

It incorporates MPI advanced technologies, such as VCE™ , mDrive™ and/or PHC™ optional or as an upgrade in the field.

![]() Characterizing Semiconductor Devices at Wafer Level

Characterizing Semiconductor Devices at Wafer Level

Video Copyright© Compound Semiconductor Applications (CSA) Catapult

Features & Benefits

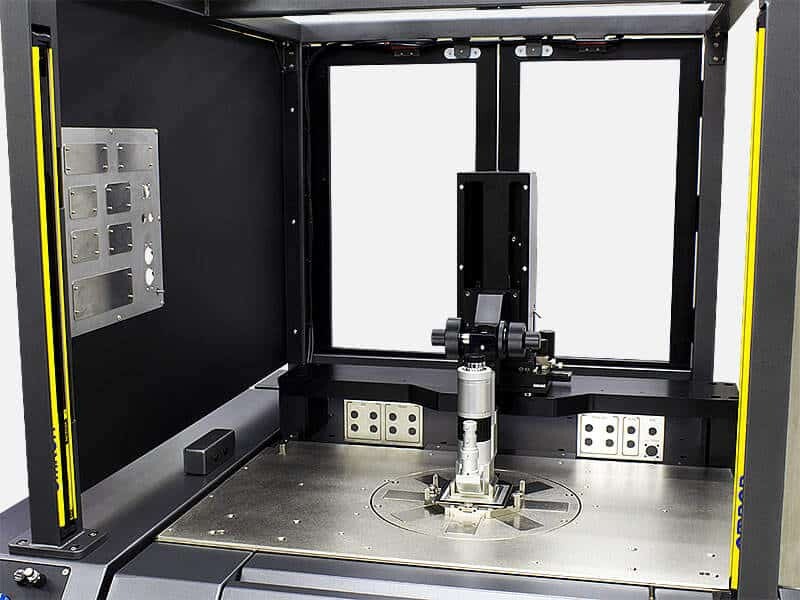

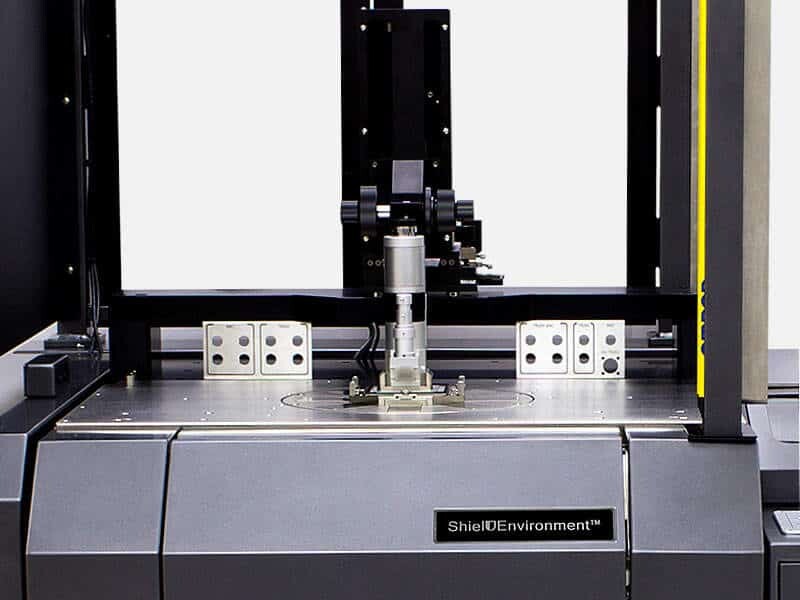

ShielDEnvironment™

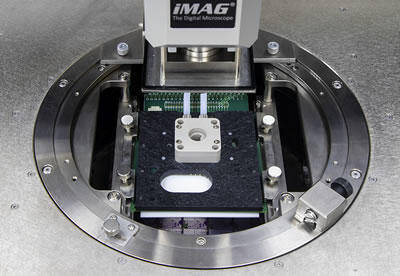

MPI ShielDEnvironment™ is a high performance local environmental chamber providing excellent EMI- and light-tight shielded test environment for ultra-low noise, low capacitance measurements.

To prevent arcing between chuck and platen, TS2000-HP platen is specially designed with MPI advanced ArcShield™.

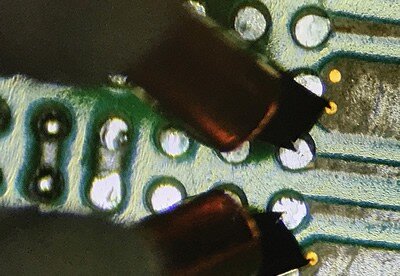

High Voltage, High Current and Ultra High Power Probes

MPI High Power probing solutions include the dedicated high current probes which use MPI propriety multi-contact tips for reduced contact resistance. MPl’s high voltage probes are capable of low leakage current measurements during high voltage tests up to 3 kV triaxial or 5 kV & 10 kV coaxial set-ups and up to 600 A.

MPI’s high-power probe card suspending arcing up to 10 kV and offering unique testing possibilities up to 150°C as well.

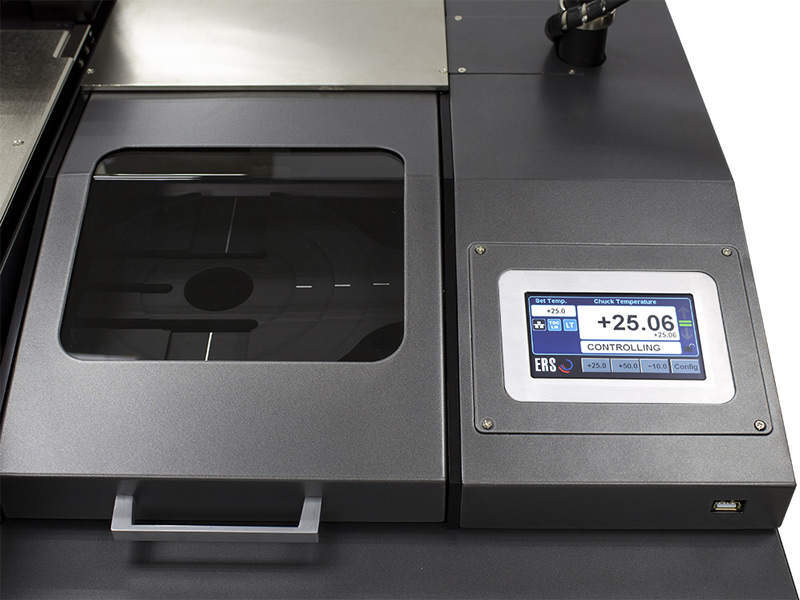

Hot/Cold Wafer Swaps at Set Temperatures

The automated single wafer loader and the safety test management provide a unique capability to load/unload wafers at any chuck temperatures. Cooling down or heating up to ambient is not required anymore to load or unload a wafer. This saves major down time and increases the overall MPI Test Systems efficiency significantly. Necessary settings are protected by a convenient supervisor log-in procedure.

MPI TS2000-HP shares the same standard features, such as, thermal chuck integration, Safety Test Management™, automated single wafer loader, vibration isolation, and integrated prober control of the TS2000-SE system.

Feel the Difference

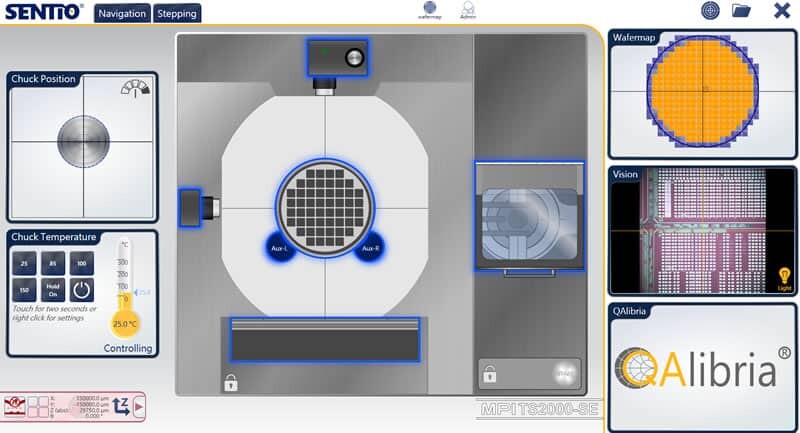

Software Suite SENTIO®

MPI automated engineering probe systems are controlled by a unique and revolutionary, multi-touch operation SENTIO® Software Suite – simple and intuitive operation saves significant training time, the Scroll, Zoom, Move commands mimic modern smart mobile devices and allows everyone to become an expert in just minutes. Switching between the active application and the rest of the APPs is just matter of a simple finger sweep.

For RF applications, there is no need to switch to another software platform – the MPI RF calibration software program QAlibria® is fully integrated with SENTIO® – for ease of use by following a single operational concept methodology.