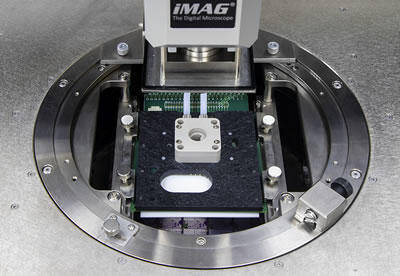

TS3500 Series with WaferWallet® = Accuracy + Flexibility + Automation

The MPI TS3500 is the entry level probe station enabling automation at lowest cost by using ambient or hot only thermal chucks. In parallel, there is no limitation on the possible options or field upgrades even up to fully shielded, advanced probe station.

TS3500-IFE and TS3500-SE are equivalent in features to MPI’s well-known and established TS3000-IFE and TS3000-SE 300 mm probe stations with the added fully-automated capability by configuring or upgrading with MPI’s unique WaferWallet® or WaferWallet®MAX. MPI’s solution is lowering the customer’s overall cost-of-test by providing full automation for less than other vendor’s semi-automated products.

It incorporates MPI advanced technologies, such as PHC™ , as a standard feature, and mDrive™ and/or VCE™ optional or as an upgrade in the field.

Features & Benefits

IceFreeEnvironment™

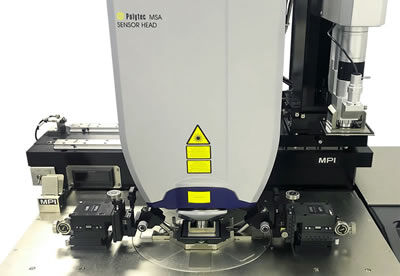

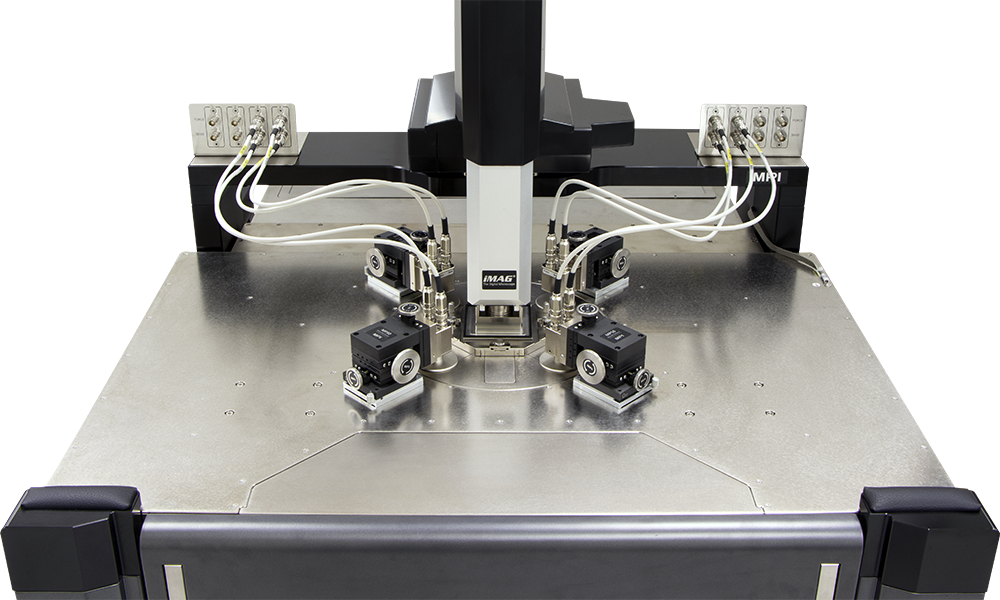

Incorporating MPI’s IceFreeEnvironment™ the TS3500-IFE accommodates testing with MicroPositioners and probe card simultaneously over a wide temperature range of -60°C to +300°C.

The design shortens the signal path thus making the probe station an ideal choice for mmW and/or load-pull applications.

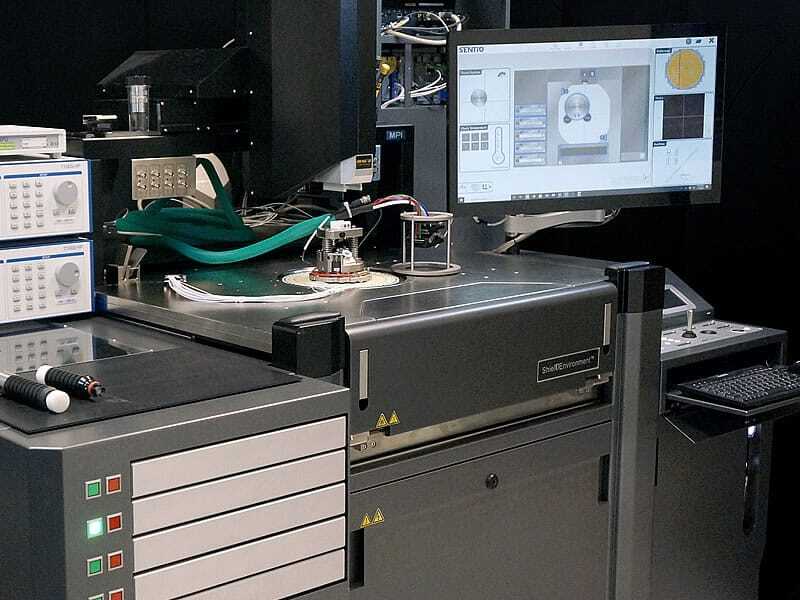

ShielDEnvironment™

MPI ShielDEnvironment™ is a high performance local environmental chamber providing excellent EMI- and light-tight shielded test environment for ultra-low noise, low capacitance measurements.

Easy to reconfigure with best EMI- and light shielding on the market, that is MPI ShielDCap™ – a lot of little things which make the difference in simplifying day by day operations.

The WaferWallet®

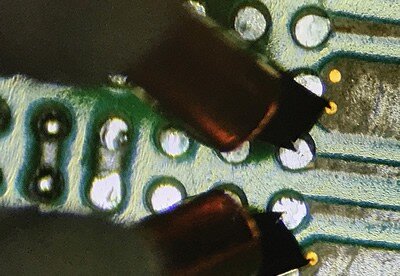

Common practice for Device Characterization in the Modeling and New Technology Development processes is to extract data from a typical few wafers via extremely accurate IV-CV, 1/f, RF, mmW, and Load-pull measurements.

MPI’s WaferWallet® extends the TS3500 series automation without compromising measurement capability. The WaferWallet® is designed with five individual trays for manual, ergonomic loading of 150, 200, or 300 mm “modeling” wafers. Fully-automated tests with up to five identical wafers at different temperatures are now possible.

The WaferWallet® MAX

MPI’s WaferWallet® MAX is easy field upgradable to address the demand for faster time to market, collecting data from multiple 150 or 200 or 300 mm SEMI standard cassette.

Including advanced alignment technologies for pre-aligner and cassette scanner, optional top or bottom Wafer ID Reader and fully automatic exposure control, the WaferWallet® MAX is also available as an option for fully-automated measurements.

Hot and Cold Wafer’s Swapping

Returning the chuck to ambient is no longer required during the wafer loading and unloading process. With the WaferWallet®, MPI provides valuable time savings via a unique capability of load/unloading wafers while the chuck remains at any test temperature.

Celadon’s Indexer™

The patented Indexer™ from Celadon is the industry’s first automatic, up to 5 probe card changer. The combination with WaferWallet® (up to 5 wafers) or WaferWallet® MAX (up to 25 wafers) offers unsurpassed flexibility and automation for advanced device modeling and wafer level reliability measurements.

- Can support up to five VC20™’s with Advanced Cantilever™ technology, at any variety and configuration

- Card changes are complete in seconds

- Fully programmable and SENTIO® integrated

- Compatible to off-axis Probe-To-Pad-Alignment (PTPA) on TS3500 Series

- Tested for hundreds of thousands of touchdowns

Test Automation

Simple and cost-effective manual in-tray wafer alignment via notch indicator makes initial wafer loading fast and reliable. Dependent upon operational methodology, other options include wafer Pre-aligner, ID reader or PTPA capability on the TS3500-SE are additional features increasing levels of automation.

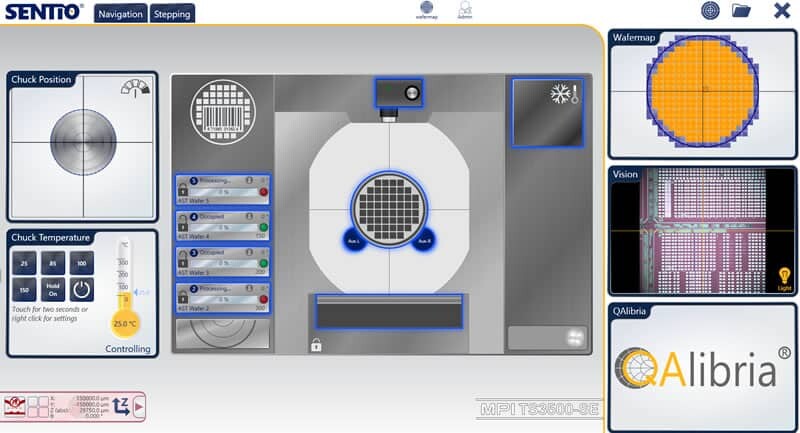

SENTIO® Dashboard

MPI’s SENTIO® 3.0 Software Suite with advanced GUI design is based on the revolutionary patented technologies:

- Multi-touch, intuitive operation

- Single window GUI, like common mobile devices

- Dashboard view of the system status for simplified navigation

- Intelligent, predictable operational guidance

- Free upgrades for the life of the probe station

With a simple view of the WaferWallet®Dashboard, the operator can recognize the loaded or empty trays, wafer diameter

(150 or 200 or 300 mm), flat/notch orientation, wafer ID (if applicable), percentage of WaferMap tested and much more.