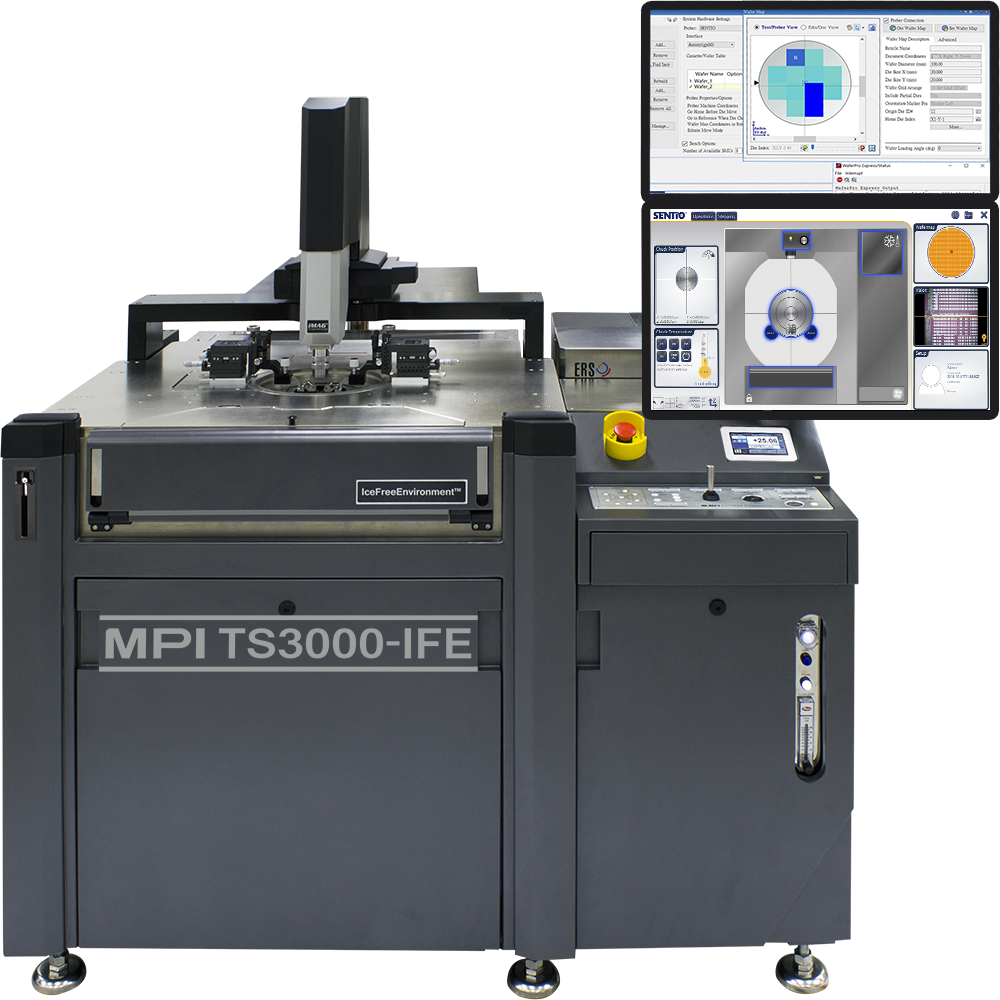

MPI TS3000 and TS3000-IFE Probe System

The MPI TS3000 is the entry level probe station enabling automation at lowest cost by using ambient or hot only thermal chucks. In parallel, there is no limitation on the possible options or field upgrades with IceFreeEnvironment™ , ProbeHoverControl (PHC), mDrive™ and/or VCE™ .

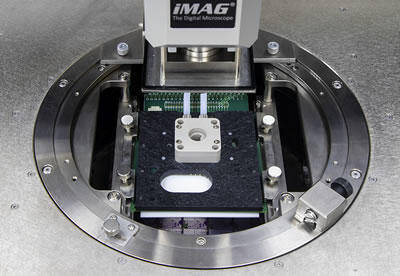

The TS3000-IFE from MPI is an automated 300 mm probe system, specially designed for Product Engineering, Failure Analysis , Design Validation, Wafer Level Reliability , Silicon Photonics and RF & mmW applications and offers:

- Maximum on temperature range -60°C to +300°C

- Maximum on flexibility

- Minimum cable distance to functional testers with a design specific cable interface for better measurement directivity

- Minimum platen-to-chuck height for optimal mmW & internal node probing

- Minimum system footprint by integrating the thermal system’s chiller “inside”

which combined together make the TS3000-IFE probe station unique to MPI Corporation and to the product engineering market.

It incorporates MPI advanced technologies, such as PHC™ , as a standard feature, and mDrive™ and/or VCE™ optional or as an upgrade in the field.

Features & Benefits

Large Probe Platen

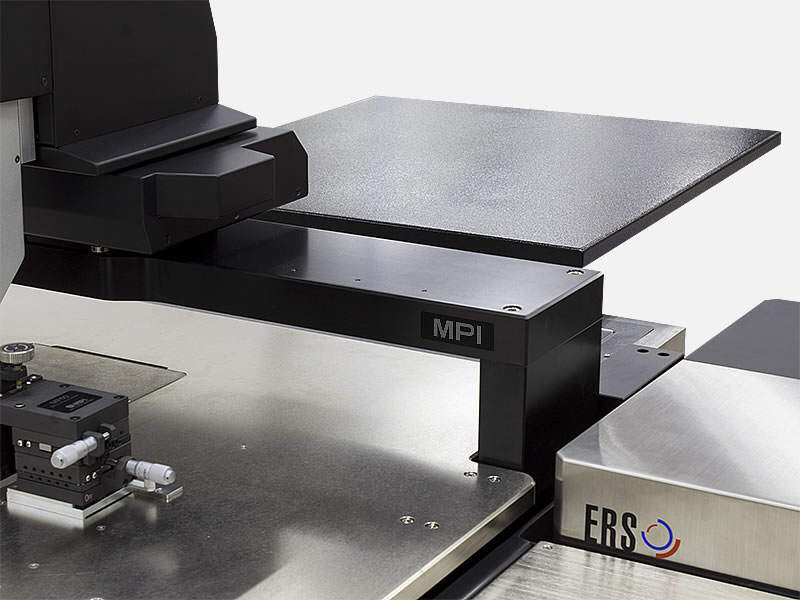

TS3000-IFE provides large, easily accessible probe platen in order to accommodate up to 12x DC or 4x RF MicroPositioners with minimum of platen-to-chuck height.

Integration of Load-Pull Tuners or larger area MicroPositioners makes TS3000 system an idea choice for RF and mmW measurements.

The probe platen is actively cooled to avoid thermal drift especially at 300°C.

Easy Wafer Loading

The dual front door access and the unique chuck design allows easy loading / unloading procedure for 150, 200, 300 mm wafers, wafer fragments or even small down to 5×5 mm ICs.

AUX chucks are both located in front where can be loaded / unloaded very conveniently. No roll-out stage allows for a simple method of automation for RF calibration and probe card cleaning.

Integrated Hardware Control Panel

The intelligent hardware control panel is completely integrated into the probe system and is designed based on decades of experience and customer interactions to provide faster, safer and convenient system control and test operation. The keyboard and mouse are strategically located to control the software if necessary and will also control the Windows® based instrumentation.

Thermal Chuck Integration

Due to smart chiller integration, the TS3000 series provide optimized footprint for saving the valuable space in the Lab.

Together MPI and ERS designed the New 300 mm Thermal Chuck AirCool® PRIME technology family, offering unsurpassed thermal flexibility with reduced soaking time by 60%, and the largest variety of thermal ranges on market.

Reduced transition time, improved electrical performance, easier testing under inert-gas atmosphere, and field upgradability are additional values of the AirCool® PRIME thermal chuck systems.

The thermal systems can be operated by using the fully integrated touchscreen display, placed at convenient location in front of the operator for fast operation and immediate feedback.

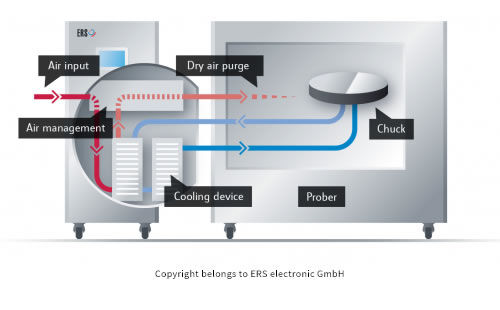

ERS Patented AC3 Cooling Technology Incorporated

These chucks incorporate the patented AC3 cooling technology and self-management system to purge the MPI TS3000-IFE IceFreeEnvironment™ using recycled cooling air, thus drastically reducing air consumption 30% to 50% as compared to other systems on the market.

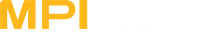

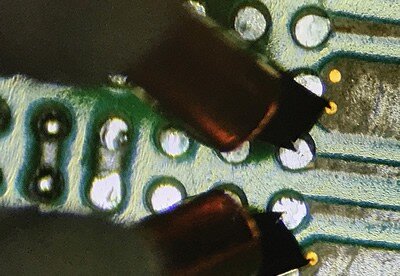

Probe Card & MicroPositioners – Simultaneously

Single probes, low-profile probe card holder for 4.5” x 11” probe card, and lower plate to chuck distance are ideal for simultaneous probing with passive / active high impedance probes, especially at negative temperatures; making the system a perfect choice for Design Validation and / or Failure Analysis work.

Safety Test Management™ (STM) System

Unique STM system prevents opening of the doors during testing – your measurement results are safe. Accidental opening of any system door during a negative chuck temperature is not possible on any event. Furthermore an intelligent dew point control routine avoids acumination during cold testing. The system automatically monitors the flow of CDA or Nitrogen. If the flow is interrupt or insufficient the STM™ turns the chuck automatically into a safe mode – heat the chuck as fast as possible to above dew point. MPI STM™ is the feature that makes measurements with TS3000 safer, more reliable and convenient by automatically maintaining a safe test environment.

Instruments Integration

The optional instrument shelf reduces cable lengths and increases measurement dynamic and directivity at RF and mmW applications.

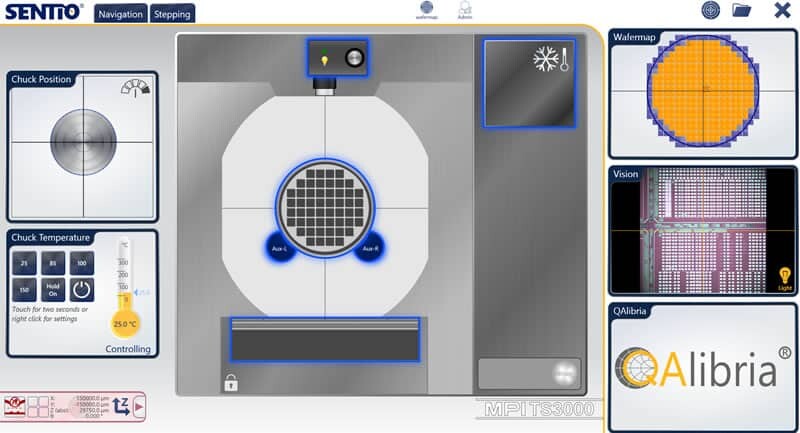

Software Suite SENTIO®

MPI automated engineering probe systems are controlled by a unique and revolutionary, multi-touch operation SENTIO® Software Suite – simple and intuitive operation saves significant training time, the Scroll, Zoom, Move commands mimic modern smart mobile devices and allows everyone to become an expert in just minutes. Switching between the active application and the rest of the APPs is just matter of a simple finger sweep.

For RF applications, there is no need to switch to another software platform – the MPI RF calibration software program QAlibria® is fully integrated with SENTIO® – for ease of use by following a single operational concept methodology.