MPI MicroPositioners

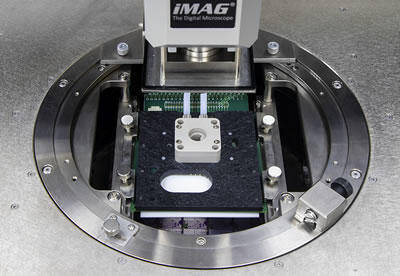

MPI offers a wide variety of backlash-free MicroPositioners to address every operational and measurement condition. These vary from small footprint to micrometer driven high resolution positioners for RF and mmW applications.

Features & Benefits

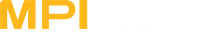

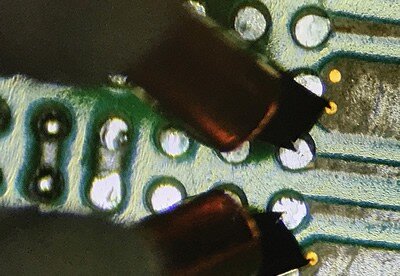

Contact Quality

Unified Z-direction, ergonomic operation, and magnetic bases with extreme strong holding power enable fine probe placement for high contact quality producing unsurpassed measurement results.

The MPI MicroPositioners are designed with universal probe interface compatible to all probe arms for ease of application specifics adaptations. Design varieties allow operators to choose MicroPositioners which fit their operational familiarity thus providing immediately proficiency.

Easy Upgrade

The MPI self-developed MicroPositioners are designed without compromise. The full carbon-steel structure enables stable contact over long periods of time and superior positioning accuracy.

Product – Application Matrix

| MicroPostioner | Coax | |||||||

|---|---|---|---|---|---|---|---|---|

| MP25 | ||||||||

| MP40 | ||||||||

| MP50 | ||||||||

| MP60 | ||||||||

| MP60-MR | ||||||||

| MP80 MP80-DX | ||||||||

| PMP60 | ||||||||

| PMP80 |

● recommended ○ available