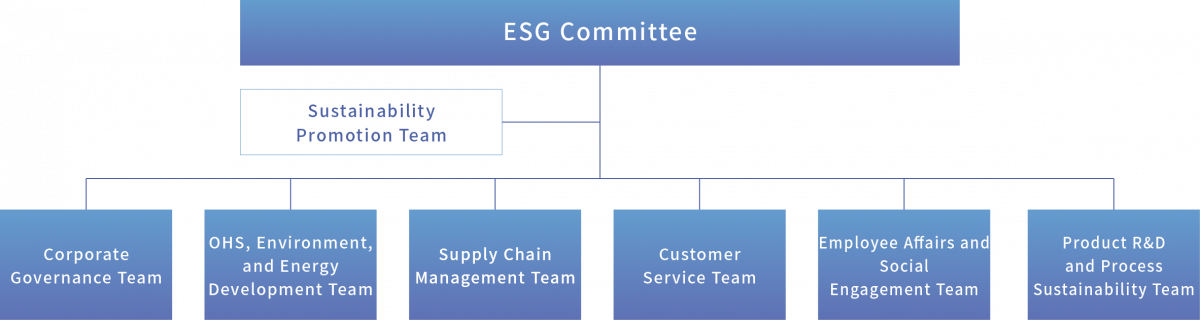

Sustainable Management Organization

To implement sustainable development, we build a business environment, fulfill corporate social responsibility, and implement corporate governance to practice our sustainable development initiative. Apart from establishing the “Business Sustainable Development Policy” and “Business Sustainable Development Procedure” in accordance with international standards and domestic regulations, we also formed the ESG Committee in 2022 to hold a committee meeting quarterly on principle. The committee is chaired by the president, senior officers of departments and offices are the members, and different teams were also established under the committee by corresponding departments. In addition to identifying and assessing ESG risks and planning counteractions ever year, the committee also accomplishes the stage targets based on the sustainable development policy to implement sustainable development actions through a top-down governance model.

Organization Chart of MPI ESG Committee

Major Duties of ESG Committee and Teams

| ESG Committee | Plan strategies and goals for sustainable development; establish annual management approaches and implementation plans for sustainable development; and supervision and audit of performance |

| Sustainability Promotion Team | Implementation of committee assignments, schedule planning, and data collection, analysis, and integration |

| Corporate Governance Team | Planning and implementation of corporate governance, business continuity, and assessment of climate-related financial impacts |

| OHS, Environment, and Energy Development Team | Planning and implementation of occupational safety, environmental management, and energy management |

| Supply Chain Management Team | Planning and implementation of supply chain management, evaluation, and audit; supplier ESG and RBA-CoC promotion |

| Customer Service Team | Concerns about and response to active/passive customer demands and issues |

| Employee Affairs and Social Engagement Team | Planning and implementation of human rights policy, employee ethics risk assessment, employee remuneration and benefits |

| Product R&D and Process Sustainability Team | Planning and implementation of product life cycle assessment, response to and reduction of product/production line impacts |

Stakeholder Engagement

Stakeholder identification and communication are implemented every year based on each ISO management system. In 2022 we identified eight major stake holder groups, including employees, shareholders/investors, customers, distributors/dealers, government agencies/NGOs, suppliers/contractors, NPOs, and local communities. We communicate with stakeholders and gather their opinions through channels including active/passive official documents, question sur veys, evaluations and audits, onsite visits, calls, meetings, opinion boxes, and emails.

| Stakeholders | Concerned Issue | Major Communication Channel | 2022 Communication Results |

|---|---|---|---|

| Employees |

|

|

|

| Shareholders/ investors |

|

|

|

| Customers |

|

|

|

| Distributors/ dealers |

|

|

|

| Government agencies/ non-governmental organizations (NGOs) |

|

|

|

| Suppliers/ contractors |

|

|

|

| Non-profit organizations (NPOs) |

|

|

|

| Local communities |

|

|

|

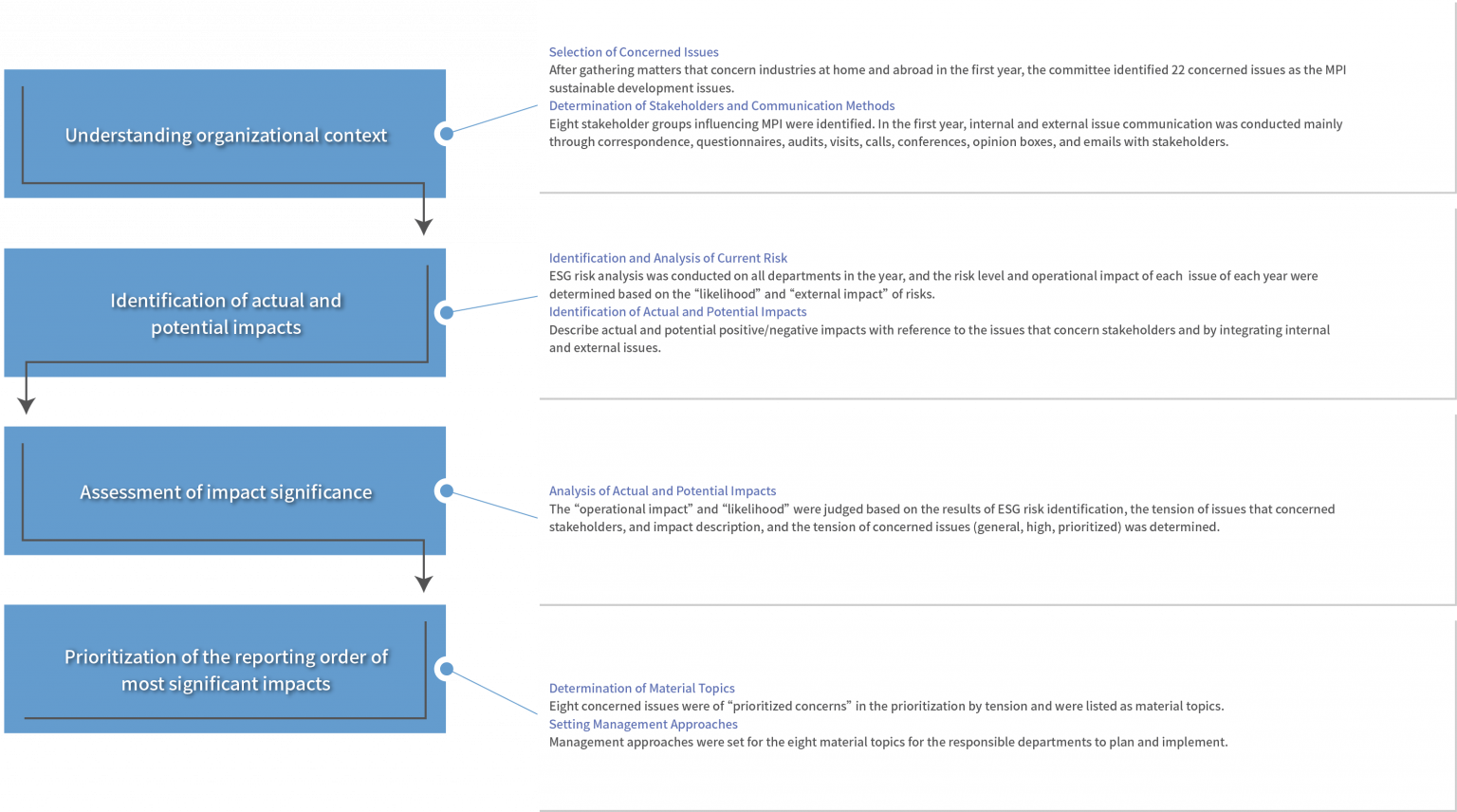

Management of Material Topics

Based on the “double materiality” principle, we double checked the tension and operational impact of issues that concern stakeholders. Then, through the thorough discussion of the committee and teams in terms of the four steps in GRI 3: Material Topics 2021, we determined and prioritized the material topics and set the management approaches.

Selection of Concerned Issues and Material Topics

| Environmental | ||

|---|---|---|

| No. | Concerned Issue | Material Topic |

| 1 | Raw materials use and management | |

| 2 | Energy | |

| 3 | GHG Emissions | V |

| 4 | Waste and toxic substance management | |

| 5 | Water | |

| 6 | Climate-related risks and opportunities | |

| 7 | Green procurement | |

| Social | ||

|---|---|---|

| No. | Concerned Issue | Material Topic |

| 8 | Human rights policy | |

| 9 | Talents Cultivation and Retention | V |

| 10 | Occupational safety and employee health | V |

| 11 | Remuneration and Employee Care | V |

| 12 | Social care and welfare | |

| Governance | ||

|---|---|---|

| No. | Concerned Issue | Material Topic |

| 13 | Product and service quality | |

| 14 | Product Information | V |

| 15 | Sustainable Development | V |

| 16 | Corporate governance and ethical corporate management | |

| 17 | Risk management | |

| 18 | Operational performance (shareholder rights and interests) | V |

| 19 | Compliance with laws and regulations | |

| 20 | Business continuity | |

| 21 | Information security | |

| 22 | Supplier Management | V |

Matrix of Material Topics

| Material Topic | Positive/ Negative Impact | Management Approach | Assessment and Management Method |

|---|---|---|---|

| Product Information |

|

|

|

| Operational Performance |

|

|

|

| GHG Emissions |

|

|

|

| Occupational Safety and Employee Health |

|

|

|

| Remuneration and Employee Care |

|

|

|

| Talents Cultivation and Retention |

|

|

|

| Sustainable Development |

|

|

|

| Supplier Management |

|

|

|

Energy

We are committed to energy conservation, carbon reduction, and hazardous substance reduction to minimize environmental impact. Every plant is established in compliance with the local environmental protection laws and regulations and achieves a green environment at high standard. Hence, we began to implement and passed the certification of the ISO 14001 Environmental Management System (EMS)in 2016. In 2022 we passed the re-verification and obtained the certificate valid until September 19, 2025. Additionally, to enhance energy efficiency, we already implemented the ISO 50001 Energy Management System (EnMS) in 2016 and have since maintained its operation. Through the operation of these management systems, we review the environmental impacts of every process and make continual improvement.

| Rate of Achieved Electricity Conservation in 2020 | Rate of Achieved Electricity Conservation in 2021 | Rate of Achieved Electricity Conservation in 2022 |

|---|---|---|

| 1.40% | 1.43% | 1.38% |

| Focus of Energy Conservation Actions | Amount Invested (NTD thousands) | 2021-2023 Amount of Benefit (NTD thousands) | 2021Electricity Saved (kWh) | 2022 Electricity Saved (kWh) | Expected 2023 Electricity Saved (kWh) | Energy Conservation in 2021-2023 (Gigajoules, GJ) |

|---|---|---|---|---|---|---|

| Replacement, optimized control, and periodic maintenance of air-conditioning equipment including the cooling water pumps, chilled water pumps, cooling towers, and main chillers | 2,385.00 | 2,222.20 | 196,086.05 | 270,354.01 | 274,389.73 | 2,666.99 |

Waste

To effectively clean up waste, prevent environmental pollution, maintain environmental sanitation, and further realize the recycling, reduction, and de-harming of waste, we have established the “Waste Management Operation Instructions” for the sorting, central disposal, and reporting of waste by law. Based on their permits for hazardous waste and non-hazardous waste, we hire qualified contractors to handle waste clearance and disposal. We also continuously advocate waste reduction to minimize the environmental impact of our activities and ensure no environmental pollution or impact on biodiversity.

| Waste Category | Treatment | 2021 | 2022 |

| Total Weight (t) | Total Weight (t) | ||

| General industrial waste | Reuse | 27.91 | 44.10 |

| Recycling | 0.00 | 0.00 | |

| Incineration | 115.08 | 114.80 | |

| Materialization | 28.37 | 27.20 | |

| Solidification | 22.09 | 0.00 | |

| Thermal treatment methods | 6.98 | 0.00 | |

| Hazardous industrial waste | Reuse | 0.31 | 0.70 |

| Incineration | 2.44 | 2.00 | |

| Materialization | 20.12 | 21.10 | |

Waste emission intensity t/ revenue of the year (NTD million) | 0.04 | 0.03 | |

Water

At MPI, the 24-hour operation of air-conditioning cooling water and the manufacturing process of production lines of plants are the major sources of water consumption, and domestic water consumption and firefighting water consumption are the secondary sources of water consumption. As we consume less water than the semiconductor industry, we are not a water-intensive business. However, we continue to adhere to our water conservation plan towards the goal of “reduction, recycling, and reuse” and emphasize the reduction of wastewater and sewage discharge. As some plants discharge wastewater and sewage due to the needs of the manufacturing process, apart from establishing the “Wastewater Treatment Operation Instructions”, we have also applied for the water pollution prevention permit by law and equipped our plants with class B dedicated wastewater and sewage treatment specialists to implement strict wastewater and sewage control so as to ensure neither influence nor impact on the biodiversity and habitats in the nearby rivers and the biodiversity in protected areas.

| 2021 | 2022 | |||

|---|---|---|---|---|

| Plant | Plants in Hsinchu | Kaohsiung Plant | Plants in Hsinchu | Kaohsiung Plant |

| Water Consumption (m3) | 137,813.00 | 11,320.00 | 144,831.00 | 14,811.00 |

| Water Discharge (m3) | 66,539.00 | 7,232.96 | 79,477.00 | 3,758.55 |

| Water Consumption (m3) | 71,274.00 | 4,087.04 | 65,354.00 | 11,052.45 |

Water Consumption Intensity Water consumption (m3)/ revenue of the year (NTD million) | 24.76 | 2.03 | 23.18 | 2.37 |

GHG emissions

Global warming is currently the most severe challenge that the world is facing. With respect to the 2009 global CO2 emissions from fuel combustion announced by the International Energy Agency (IEA), Taiwan was ranked 23rd in the world. The statistics show that Taiwan is bound to bear the international pressure for reduction in the future. We began the organization-level GHG inventory in 2022. With 2022 as the base year, we established the GHG inventory management system for all plants in the first year. It is expected that the verification of the organization-level GHG inventory will be completed in 2023. In the future we will plan GHG reduction in line with the government policy to achieve the goal of emission reduction.

| Plant | Category | 2022 (tCO2e) |

|---|---|---|

| All Plants in Taiwan | 1:Direct GHG emissions and removals 2:Energy indirect GHG emissions 3:Transportation indirect GHG emissions 4:Indirect GHG emissions from purchased goods and services 5:Indirect greenhouse gas emissions from processing and use of sold products 6:Other sources of indirect GHG emissions | 1,410.1096 17,885.6459 Insignificant 5,680.2172 Insignificant Insignificant |

Total GHG Emissions Intensity CO2e/ Revenue of the year (NTD millions) | 24,975.9727 3.9977

| |

| GHGs | 2022 (tCO2e) |

|---|---|

| CO2 CH4 N2O PFCs HFCs SF6 NF3 | 23,952.5893 151.6262 10.2903 54.5332 806.9337 0 0 |

Human Rights Policy

We fulfill corporate social responsibility (CSR) with our best efforts, value, manage, and monitor employee human rights. Based on our “Corporate SociaResponsibility Best Practice Principles”and in accordance with the international human rights conventions, we value workplace gender equality, protect the right to work of employees, and prohibit discrimination of any forms. We have also established internal regulations including the “Human Resources Management Procedures”, “Regulations for Gender Equality in Employment”, “Regulations for Measures of Prevention, Correction, Complaint, and Punishment of Workplace Sexual Harassment”, and “Code of Employee Ethics and Conduct” to protect employee human rights. Violation of employee human rights will be disciplined in accordance with the “Regulations for Employee Rewards and Disciplines”. We also continuously enhance the awareness of employee human rights and arrange education and training on the RBA-CoC and prevention of workplace sexual harassment for active employees to maintain workplace human rights.

| Human Rights Core Items | Implementation Approach | Management Measures |

|---|---|---|

| No forced labor |

|

|

| No child labor and protection for young employees |

|

|

| Humane Treatment |

|

|

| Working Hour Benefits |

| |

| Freedom of Association |

|

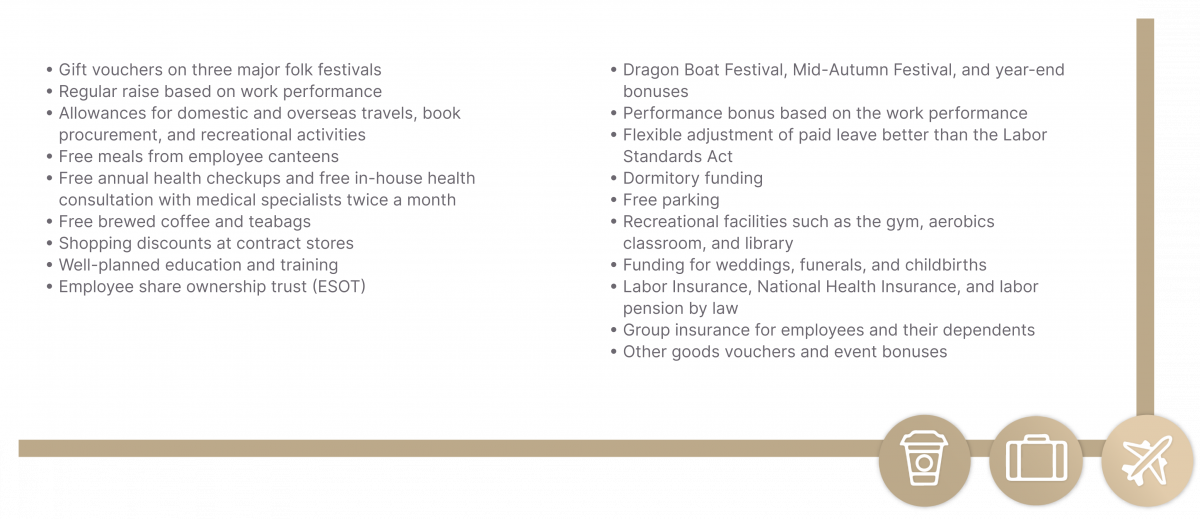

Remuneration and Benefits

In addition to abiding by the local labor laws and regulations and salary standards, we also assess the salary standards in the talents market and the industry periodically to timely adjust the remuneration and benefits for employees based on the Company’s operational performance so as to keep the median salary of non-management employees above the average in the industry and ensure the positive salary growth. In accordance with Article 19 of the Company’s Articles of Incorporation, if there is profit before tax, we should allocate 0.1-15% of the profit as the remuneration for employees. In the past three years, we have allocated an average of over 10% of profit as remuneration for employees. As the expenses on employee benefits also increase every year, showing the fruit of our profit sharing with employees. More information please see the Careers.

Employee compensation to Median Ratio

| 2020 | 2021 | 2022 | ||||

| Total (NTD thousands) | Increase/ Decrease from the Previous Year | Total (NTD thousands) | Increase/ Decrease from the Previous Year | Total (NTD thousands) | Increase/ Decrease from the Previous Year | |

| Mean employee salary | 1,071 | 15.29% | 1,096 | 2.33% | 1,210 | 10.40% |

| Mean annual total compensation for non-management full-time employees | 1,154 | 15.05% | 1,156 | 0.17% | 1,266 | 9.52% |

| Median annual total compensation for non-management full-time employees | 995 | 14.63% | 1,008 | 1.31% | 1,103 | 9.42% |

Total Amount of Compensation for Employees in Past 3 Years

| 2020 | 2021 | 2022 | ||||

| Total (NTD thousands) | Ratio to Net Income | Total (NTD thousands) | Ratio to Net Income | Total (NTD thousands) | Ratio to Net Income | |

| Compensation for employees | 73,877 | 10.34% | 71,048 | 10.24% | 127,800 | 10.53% |

| Net Income | 714,482 | - | 693,851 | - | 1,213,625 | - |

Retirement Allowance Program

Based on the applicability of the old and new systems (before and after July 1, 2005), we contribute the pension reserve for employees every month in accordance with the Labor Standards Act or Labor Pension Act. We have also established the Employee Pension Reserve Supervisory Committee to administer the affairs related to employee retirement to ensure sufficient coverage and confidence for retiring employees.

| Pension System | Old System | New System |

|---|---|---|

| Applicable Law | Labor Standards Act | Labor Pension Act |

| Method of Contribution | 2% of the total monthly salary of employees contributed monthly | 6% of the insured salary category of employees |

| Contribution Account | Labor Retirement Reserve Fund special account at the Bank of Taiwan | Employee personal account at Bureau of Labor Insurance |

| Total Amount Contributed (by 2022) | Balance of contributed: NTD 102,648 thousand | Contributed pension: NTD 79,823 thousand |

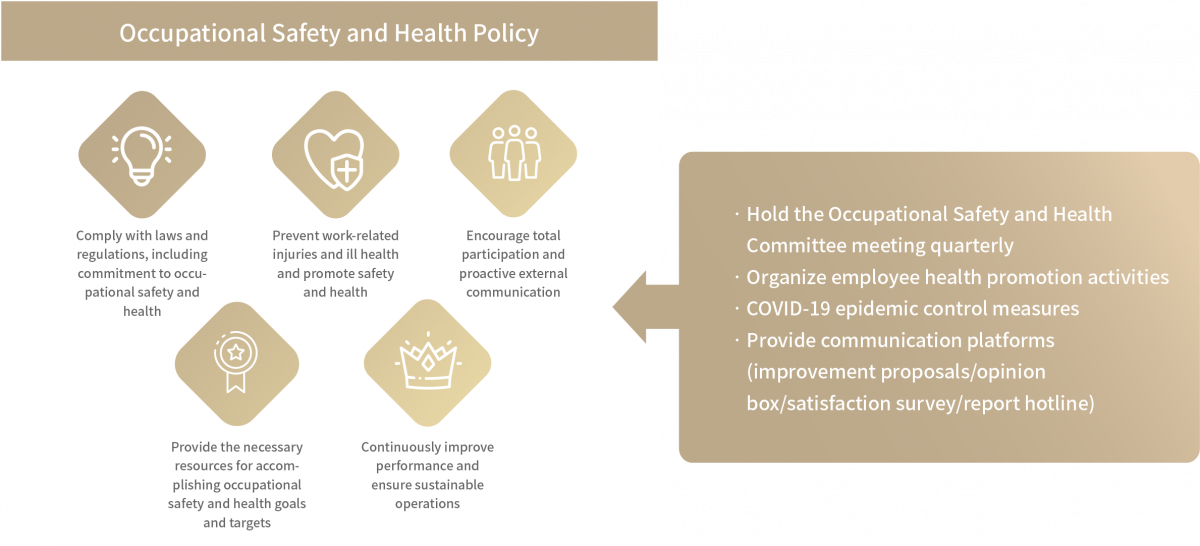

Occupational Health and Safety

Occupational safety and health are the foundation for building a friendly environment. We obtained the Occupational Health and Safety Assessment Series (OHSAS) 18001 certificate in 2016 and passed the version change certification to the ISO 45001 Occupational Health and Safety (OH&S) Management Systems in 2020. In 2022 we passed the verification of the OH&S management systems, and the certificate is valid until August 31, 2025. Through years of system implementation and third-party verification of system effectiveness, we spare no efforts in OH&S management.

Higher-risk factors that affect employee safety and health in the workplace are listed as monitoring items and under the routine supervision by dedicated personnel to reduce the probability of major accident hazards.

| Inspection Item | Frequency |

|---|---|

| Operating environment monitoring - Dust, noise, organic matters, specialty chemicals | Once every six months |

| Operation environment monitoring - Lead | Once a year |

| Periodic inspection of hazardous machines and equipment: Elevators, special equipment for high-pressure gases | Once a year |

| Electrical equipment inspection | Once every six months |

| Self-inspection | Implemented in accordance with the relevant documents and regulations |

| Fire inspection | Once a year |

In accordance with Articles 30 and 31 of the Occupational Safety and Health Act, pregnant workers are not allowed to work at a site where lead and its compounds are spread or a harmful level of radiation is present or engage in work that involves the handling of objects above a specific weight or potential hazards on the health of the fetus or the mother. As some of our production lines involve the above conditions, factory nurses voluntarily conduct health protection assessment and healthcare consultation on pregnant workers to ensure perfect protection for both the pregnant workers and their fetuses.

| Number of Employees Assessed and Consulted | |

|---|---|

| Workplace Environment Assessment and Healthcare Consultation | 22 persons |

Download Sustainability Reports and Documents

Contact

Sustainable Management Organization

Communication with Stakeholders

Management of Material Topics