Optical Sensing

OPTICAL SENSING TEST SOLUTIONS

Vertical Cavity Surface Emitting Laser (VCSEL) based optical sensing technologies are finding their way into numerous consumer (Facial Recognition, Gesture Sensing, Augmented Reality) and automotive (LiDAR and In-Cabin Monitoring) applications. MPI’s comprehensive portfolio of test and measurement solutions are ready to meet the demands of the VCSEL based optical sensing market.

MPI’s array of optical sensing solutions are well suited for the demands of both production and engineering environments. We are ready to meet customer’s critical testing and back-end processing needs:

-

- Parametric Test and Measurement

- Material Handling

- Inspection

- Wafer Level Reliability Test (WLBI)

MPI optical sensing solutions have been designed to meet the entire spectrum of VCSEL designs and configurations.

-

- Front Emitting VCSEL

- Rear Emitting VCSEL (Flip-Chip)

- Wafer, Package, & Die Level

THE TECHNOLOGY

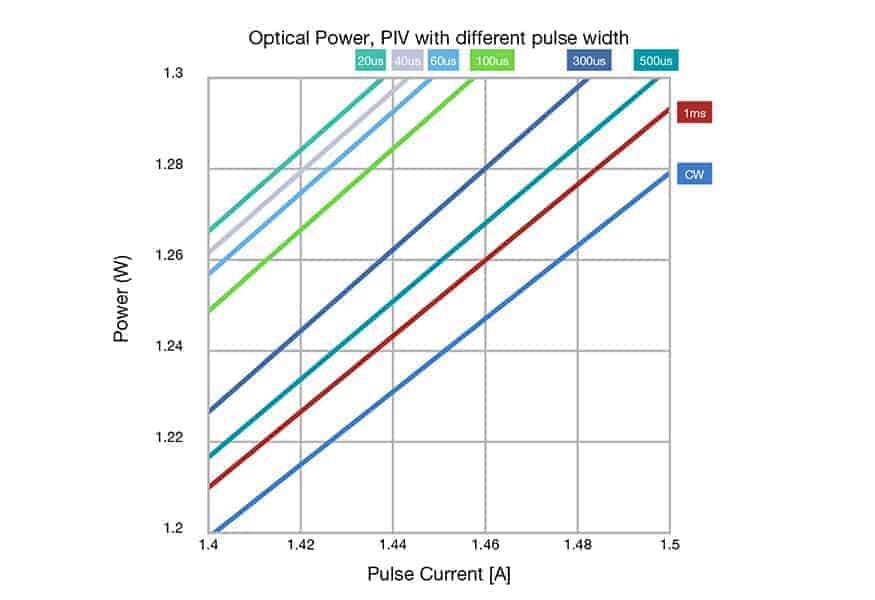

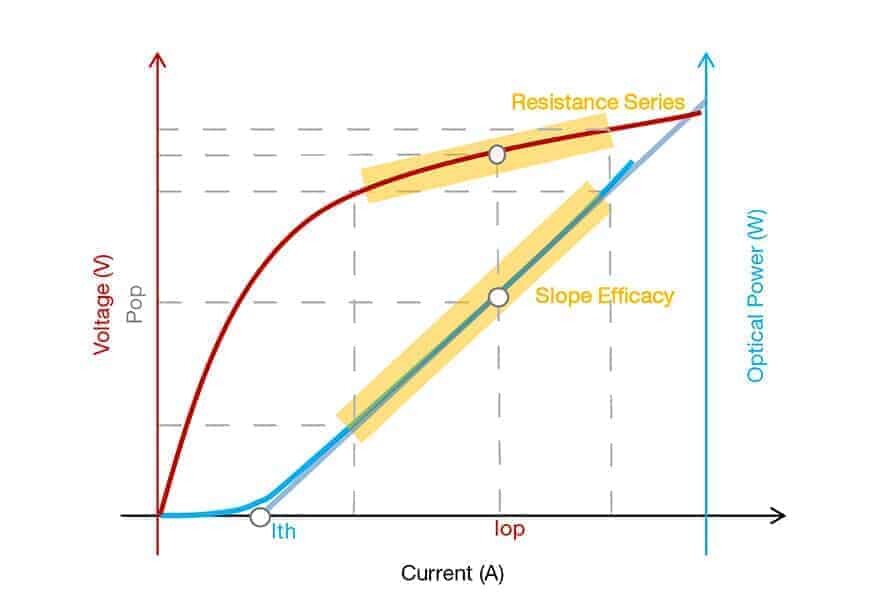

The Light-Current-Voltage (LIV) sweep test is a fundamental optical measurement used to determine the operating characteristics of devices such as laser diodes (LDs) and VCSELs.

MPI specializes in integrating a variety of Source and Measurement Units (SMU) providing accurate and synchronized power and voltage measurements in both pulsed (mS to nS) and CW modes.

-

- High speed nanosecond test instrumentation capability

- Electrical, Mechanical & Thermal system design to minimize the effects of self-heating, contact resistance and parasitics

- High speed optical measurements using integrating spheres for both low and high power VCSELs

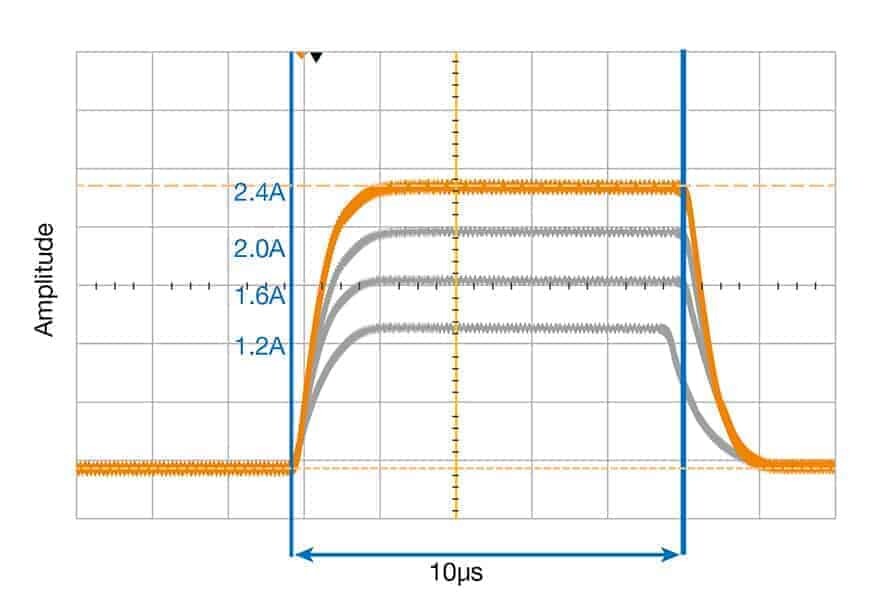

High Speed Pulsed Optical Measurements

-

- Laser Diode Driver Integration for LiDAR / Time of Flight (TOF) applications

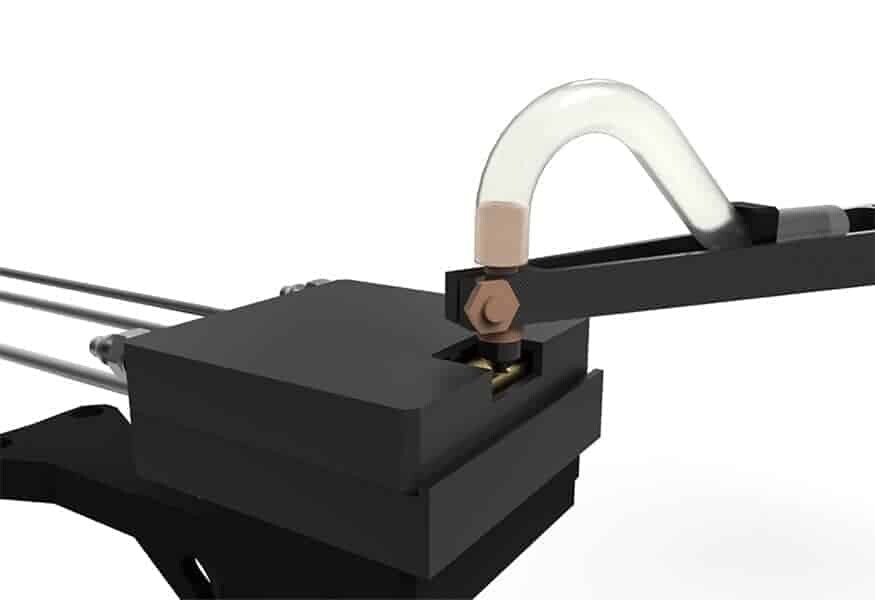

- High fidelity current stimulus control enabled by MPI’s high frequency probe card technologies

- Synchronized electrical/optical measurements and data capture

- Interleaved current pulse generation for enhanced high throughput testing

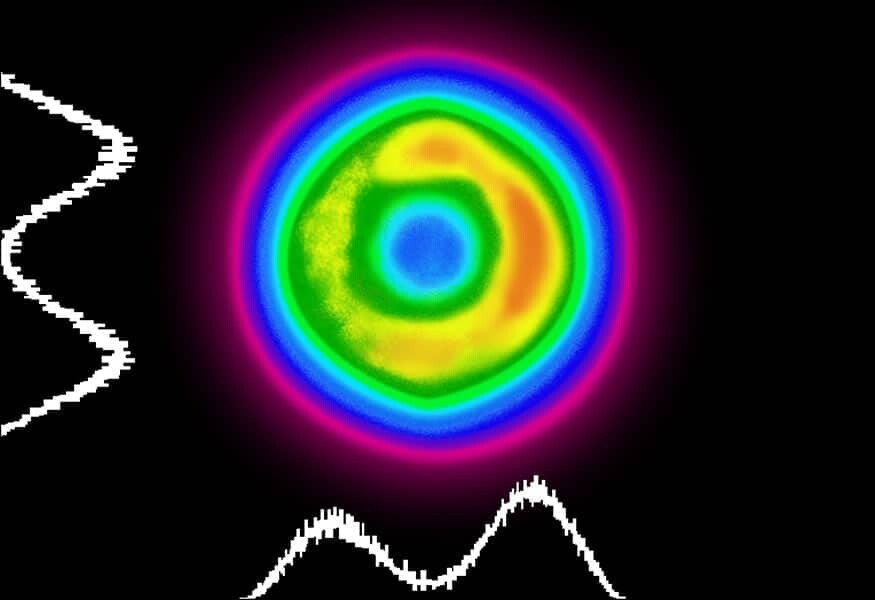

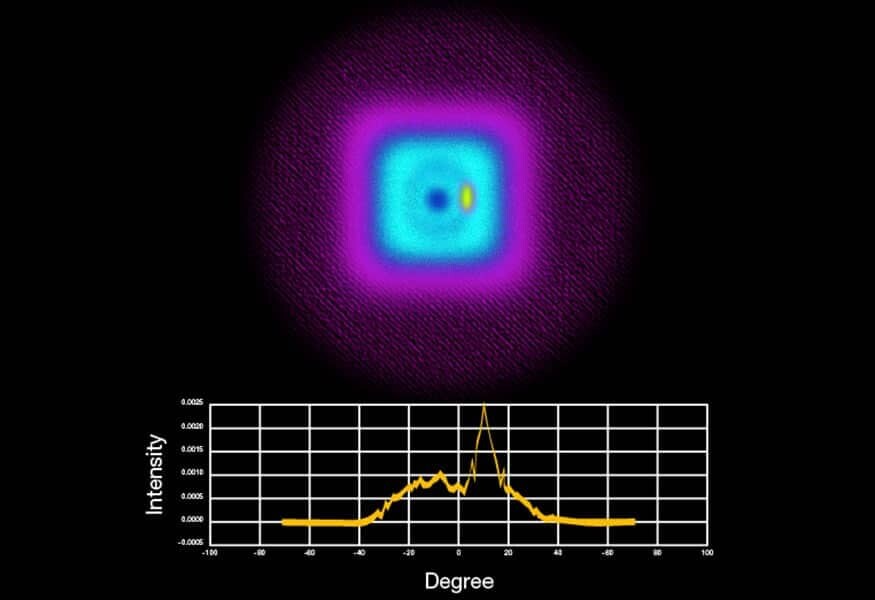

Far Field Measurements are used to characterize a VCSEL Array’s optical profile at longer working distances.

MPI specializes in:

-

- Optical system design and integration to achieve high quality Far Field images with working distances ranging from 4mm to 1.5m or more

- Typical Far Field optical measurements include:

-

- Divergence Angle

- Eye Safety

- Uniformity

- Efficiency

-

- Both Panel and Direct measurement methodologies are supported

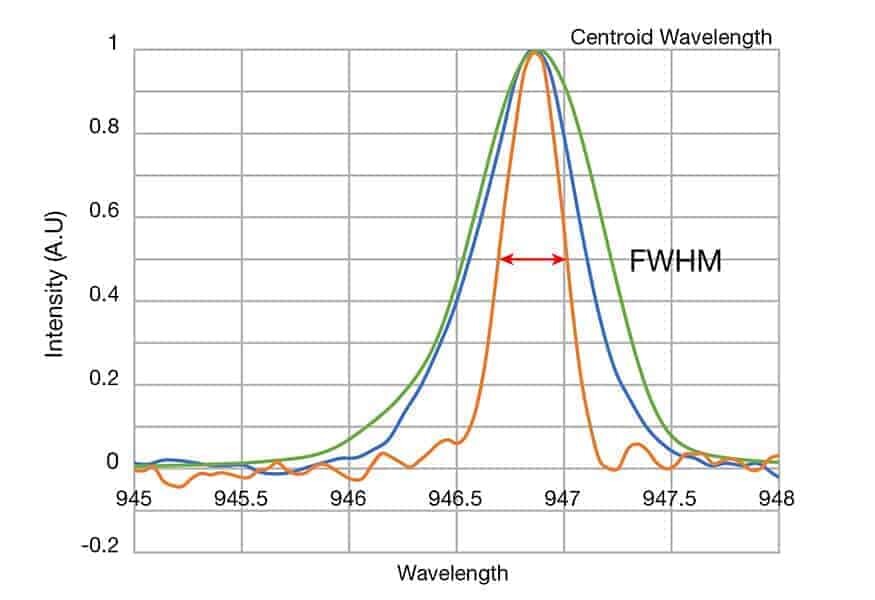

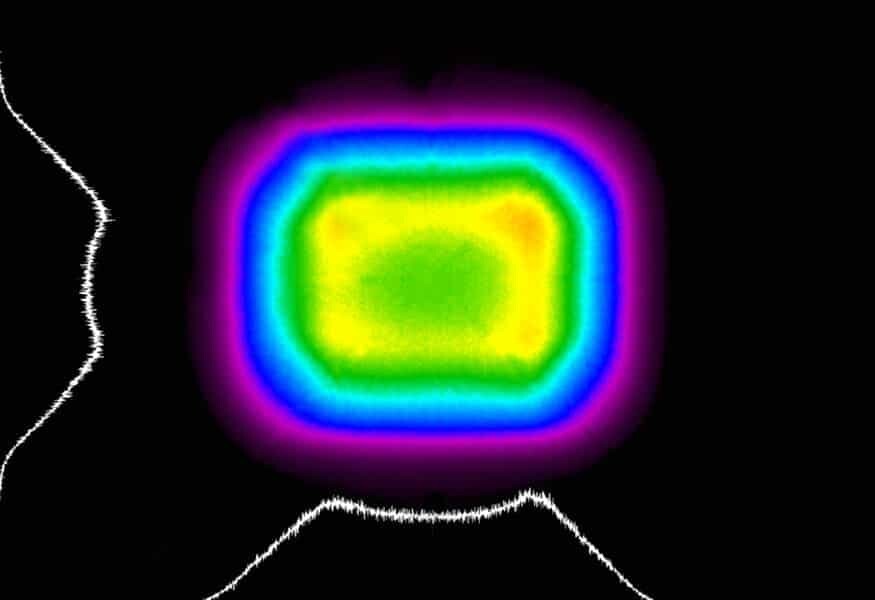

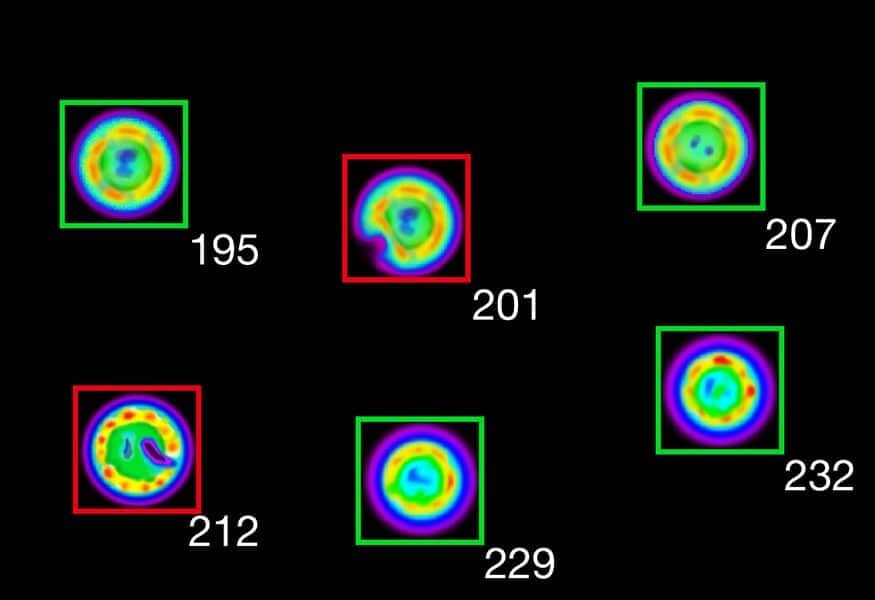

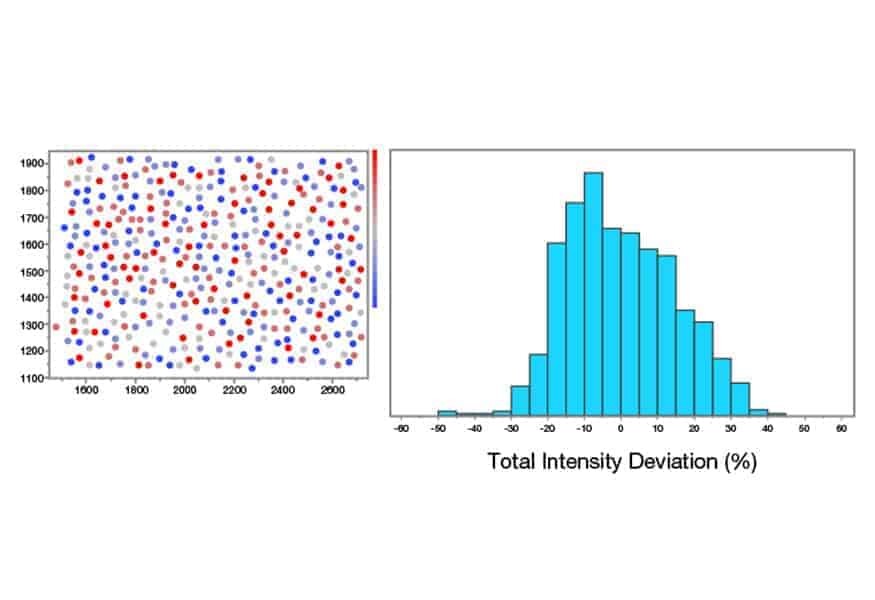

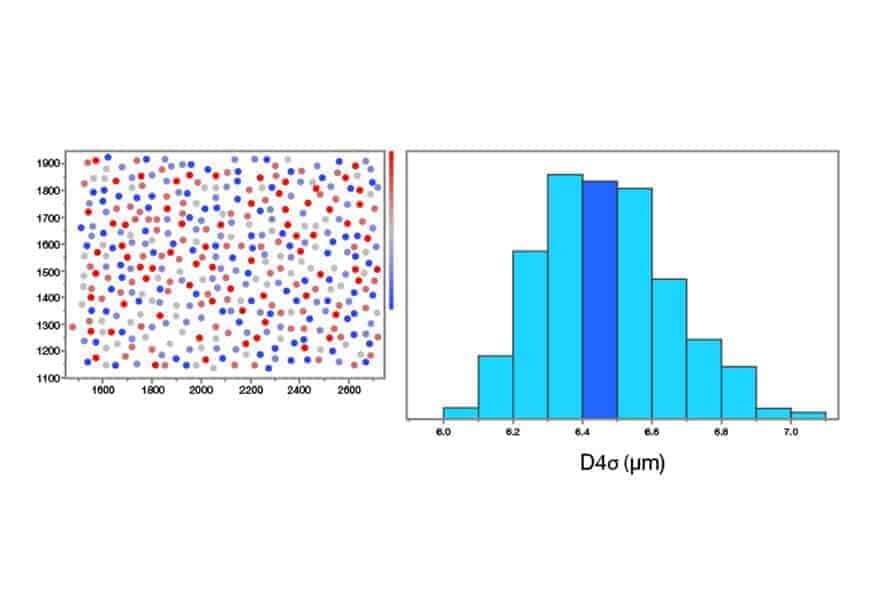

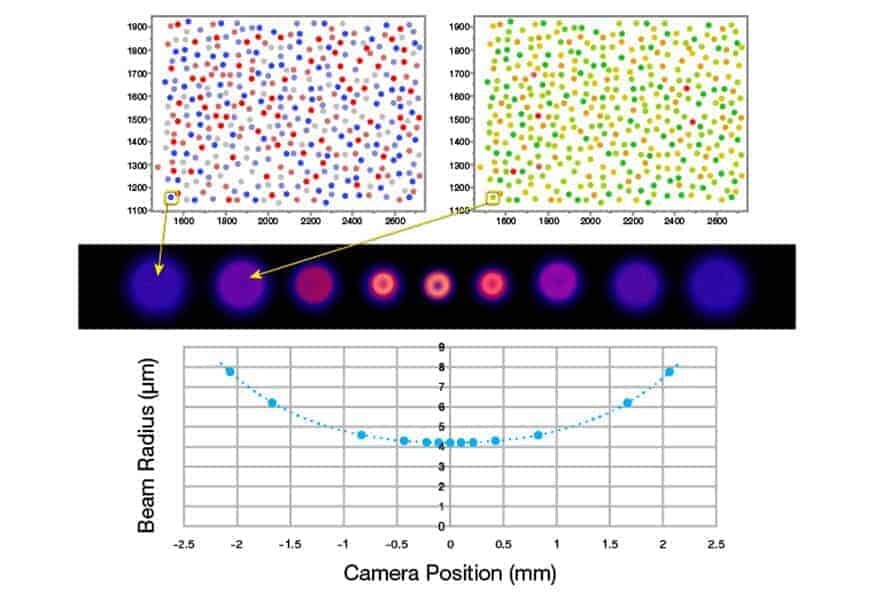

Near Field measurements are used to characterize the optical power and beam characteristics in VCSEL arrays on a per emitter basis.

MPI specializes in:

-

-

- Optical system design and integration to achieve high quality Near Field measurements for VCSELs with emitting apertures ranging from 5µm to 20µm

- VCSEL array characterization (Uniformity, Detection of faulty emitters and pass/fail grading)

- Optical Beam Characterization:

-

-

- Numerical Aperture (NA)

- Beam Diameter [D4σ (D4Sigma), D86]

- Beam Quality (M2) using sequenced near field imaging

-

-

- High speed optical measurements

-

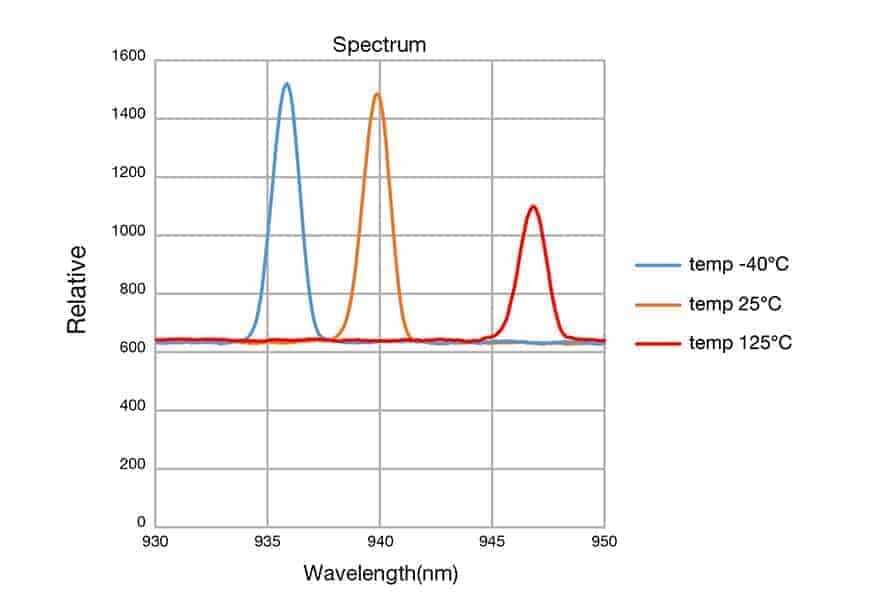

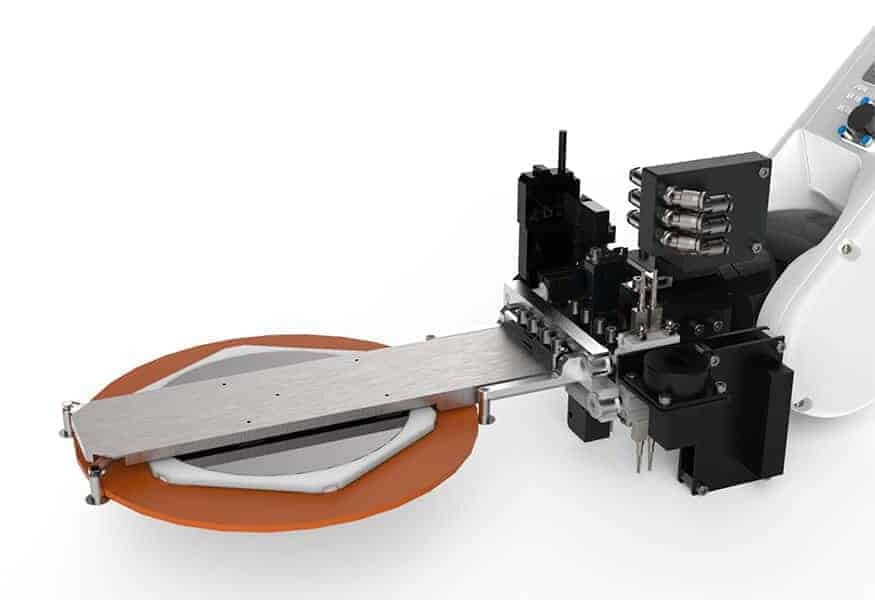

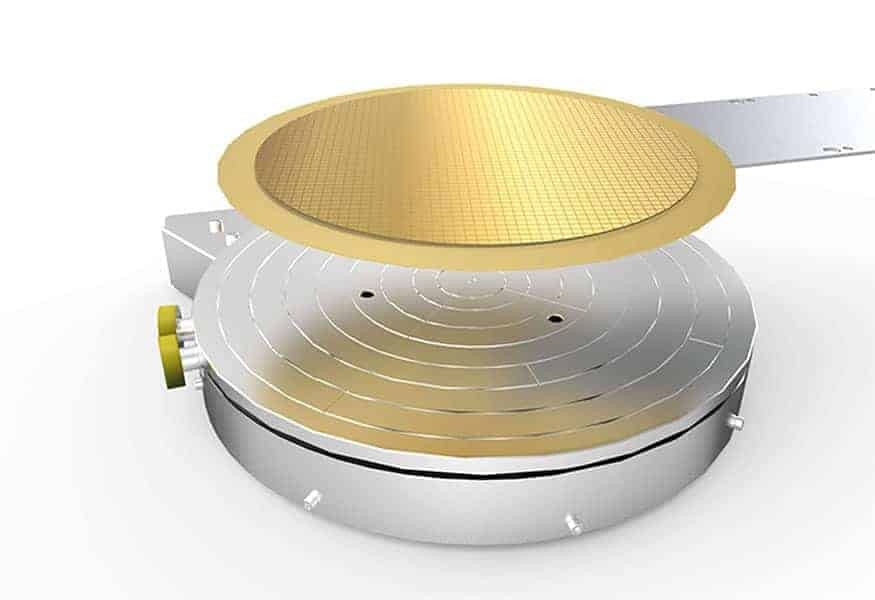

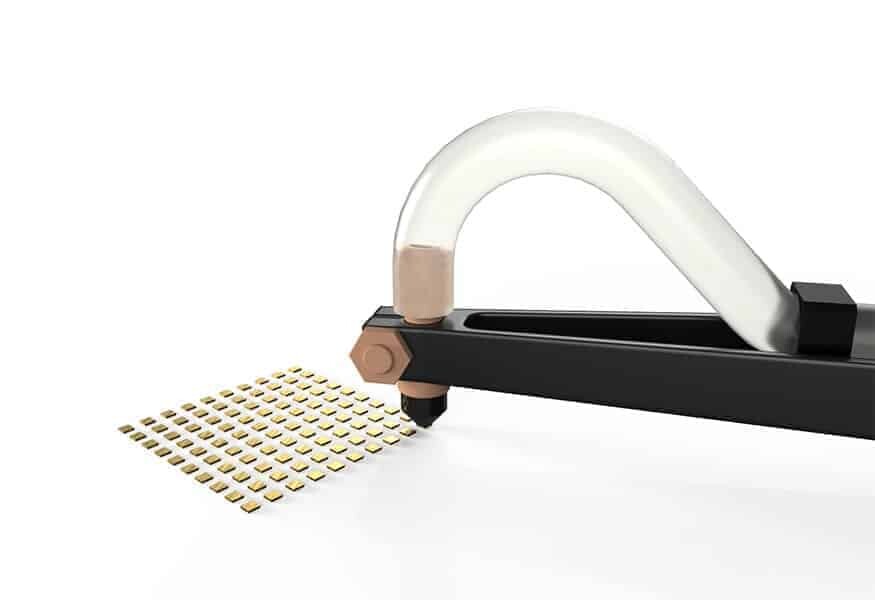

MPI’s portfolio of automated test and material handling solutions readily meet the diverse needs of the optical sensing manufacturing market. Whether it be thin wafer handling, device pick and place (PnP), extreme temperature testing or production data management, MPI has a solution that will streamline your production flow and enhance product yields.

MPI specializes in:

-

- Thin wafer handling solutions (Non-contact Bernoulli handler, Gel-Pak, and Carrier methods)

Extreme temperature testing:

-

- Wafer Test: -60°C to ~200°C

- Device Test: 0°C to 100°C

-

- Production test automation and data management

-

- Flexible recipe setting with multiple test sequence support

- Multi-die test support

- Configuration and test data management tools

-

- Thin wafer handling solutions (Non-contact Bernoulli handler, Gel-Pak, and Carrier methods)

Thin Wafer Handling Technology

Multiple thin wafer handling solutions available for different device types and manufacturing flows

Easy-to-use Software Suite

MPI’s powerful control software combines highly efficient operation with an intuitive and easy-to-use interface

-

- Flexible recipe setup enables smooth and efficient operation per customer defined test plans

- Multi-die probing capability boosting production throughput enabling lower cost of test

THE BENEFITS

Superior Optical Expertise and System Integration Capability for Customer’s Requiring High Volume Manufacturing, Development and Test of Laser Diodes

![]()

-

-

- High precision test and measurement results

-

![]()

-

-

- High quality probing with optimizing automation

-

![]()

-

-

- Proactive service and training support to keep your equipment running with minimal interruptions

-

![]()

-

-

- Controlling all aspects of mechanical/electrical device contact

-

![]()

-

-

- Customer-centric customizable solutions for your specific requirements

-

EXPLORE MORE MPI PHOTONIC SOLUTIONS

OPTICAL COMMUNICATIONS

Precision test and measurement solution for optical devices such as Photo Detectors and Laser Diodes

SILICON PHOTONICS

Dedicated SiPH on-wafer tests designed to perform repeatable low noise measurements

LED

Complete solution covers testing, sorting, and inspection from wafer to package die level

Need help or have questions?