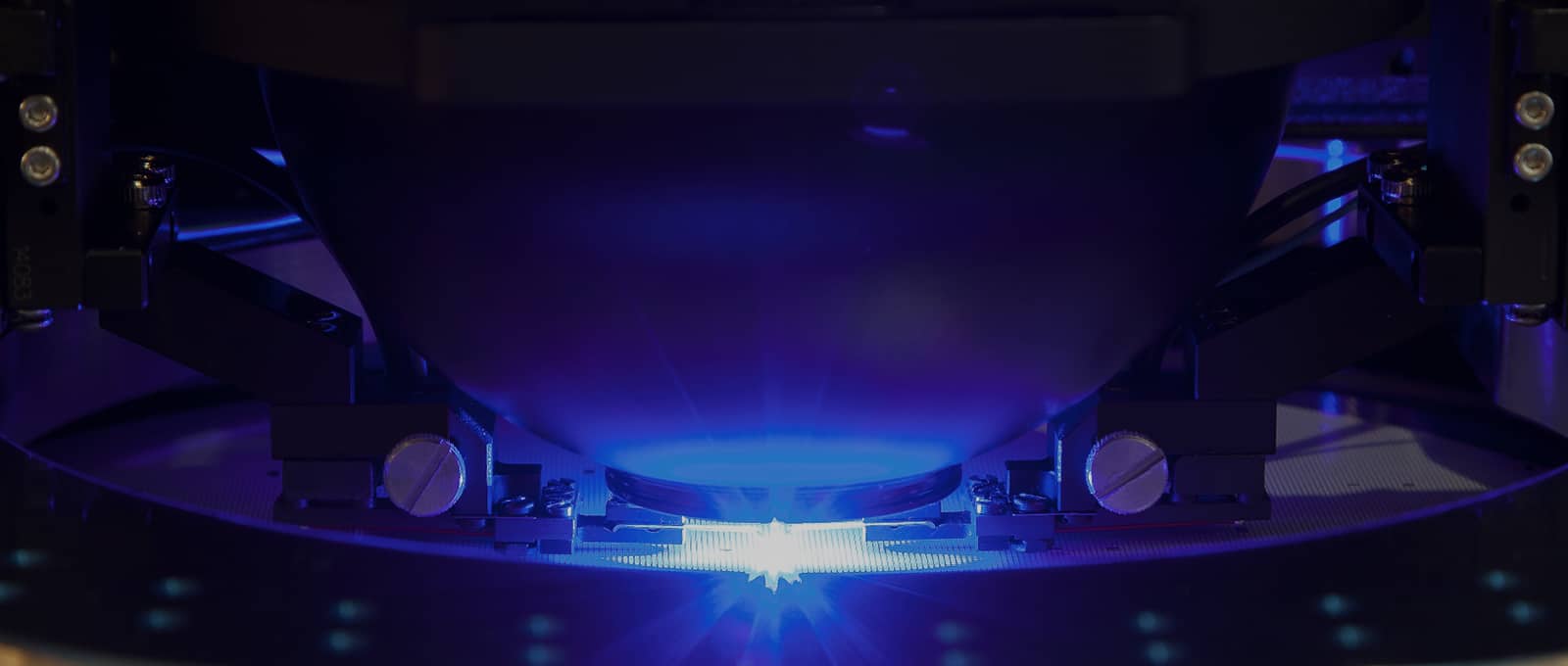

CAPELLA Series

Turnkey LED / Mini LED test solutions encompassing wafer to package level devices

CAPELLA Series Overview

MPI Photonics Automation is the industry leading provider of turnkey test solutions for the LED / Mini LED manufacturing industry. With more than 10,000 MPI probers installed worldwide, the CAPELLA series of probers have a proven track record of superior performance and reliability.

The CAPELLA series probers support electrical and optical characterization of all LED product types (Vertical chip, Lateral chip, Flip-chip) from wafer to packaged die level. Whether you need a high-performance, cost-effective or specialty prober system, MPI PA has the most comprehensive range of LED wafer/chip probers to meet your exacting requirements.

MARKETS SERVED

General Lighting

Medical & Health

Outdoor Display

Automotive Lighting

Backlighting

CAPELLA Top Prober (TP) Series Key Features

- Accurate and cost-effective production capability.

- Multi-site testing with high pin count probing capability (4 ~ 256 channels) to achieve high throughput.

- Comprehensive statistics and analysis tools for electrical / optical properties: color chromaticity (xyz), intensity, irradiance.

- Modular system design that is scalable from semi auto to fully auto operation or highly integrated cluster prober systems.

- MPI prober control software provides comprehensive control functions from basic wafer alignment, mapping, probe mark inspection to the deployment of MPI’s advanced Needle Alignment Mechanism (NAM) technology.

- The MPI Photonics Test System features a user-centric design that can be flexibly configured and programmed according to your unique test requirements.

Flexibility: With support for multiple test recipes, the user can flexibly select or modify the workflow or edit parameters according to the product and tests being performed.

Production Management: Manage lab/production data via the intuitive and easy-to-use software interface. Integrated real-time system monitoring and reporting enable a smooth and fully unattended test process.

Seamless Integration: With MPI’s extensive instrument library, the MPI test system can easily interface with mainstream third-party measurement instruments to meet your unique testing needs.

CAPABILITY

Cost Effective

Multi-site Test

Chromaticity

CONFIGURATION

Semi Auto

Fully Auto

DUT

LED

CAPELLA Flip-chip Prober (FP) Series Key Features

- Accurate and cost-effective production capability.

- Multi-site testing with high pin count probing capability (4 ~ 256 channels) to achieve high throughput.

- Comprehensive statistics and analysis tools for electrical / optical properties: color chromaticity (xyz), intensity, irradiance.

- Modular system design that is scalable from semi auto to fully auto operation or highly integrated cluster prober systems.

- MPI prober control software provides comprehensive control functions from basic wafer alignment, mapping, probe mark inspection to the deployment of MPI’s advanced Needle Alignment Mechanism (NAM) technology.

- The MPI Photonics Test System features a user-centric design that can be flexibly configured and programmed according to your unique test requirements.

Flexibility: With support for multiple test recipes, the user can flexibly select or modify the workflow or edit parameters according to the product and tests being performed.

Production Management: Manage lab/production data via the intuitive and easy-to-use software interface. Integrated real-time system monitoring and reporting enable a smooth and fully unattended test process.

Seamless Integration: With MPI’s extensive instrument library, the MPI test system can easily interface with mainstream third-party measurement instruments to meet your unique testing needs.

CAPABILITY

Cost Effective

Multi-site Test

Chromaticity

CONFIGURATION

Semi Auto

Fully Auto

DUT

LED

Mini LED

CAPELLA Die Prober (DP) Series Key Features

- Superior data correlation for package level LED test.

- Excellent test accuracy:

- Short DUT & ISP separation for optimal light collection

- Dice offset compensation - Accurate and stable temperature control with thermal chuck support.

- Programmable Pick & Place force between 5g ~ 200g.

- Fully shielded dark box design eliminates unwanted lighting interference.

- Advanced chip defect detection.

CAPABILITY

High Temp.

CSP Probing

Test Accuracy

Cost Effective

CONFIGURATION

Fully Auto

DUT

LED

More Information

Are you interested in this product and need further information?

please click below for a quick response or

Email us: pa-sales@mpi-corporation.com

Need help or have questions?