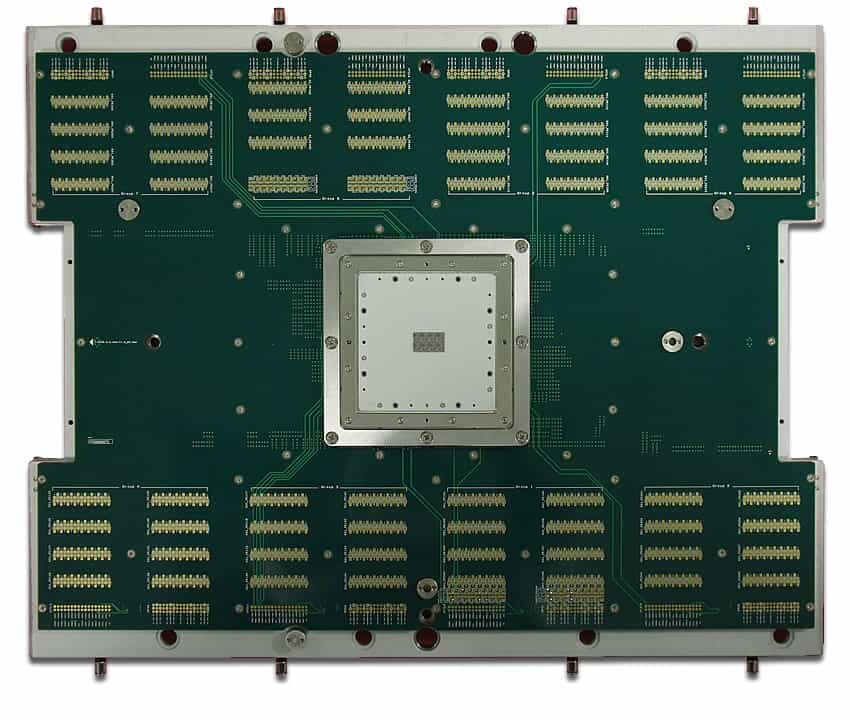

FCB Probe Card

The FCB Probe Card is the most mature technology of buckling beam probe card. It is aimed to achieve the semiconductor ship manufacture time-to-market (TTM) and cost of test (COT) demand. FCB is a proven solution for a variety of semiconductor production tests, from early engineering pilot runs to high-volume manufacturing (HVM). FCB is ready for devices requiring high signal integrity probing (SI) and/or power integrity probing (PI). Applications include cutting-edge SiPs/SoCs, WLP, graphic processors, microprocessors, industrial microcontrollers, and more. FCB probe card offers the industry’s leading cost of ownership (COO) for a wide range of DUT applications, ensuring optimal value and efficiency.

FCB Key Features

- Mature buckling beam

- Available in both flat and pointed tip

- Adapted for bond pad patterns such as full array, semi-array, peripheral and staggered chip pattern

- Provide cost-effective solution for mass production

- Compatible with MPI in-house substrates