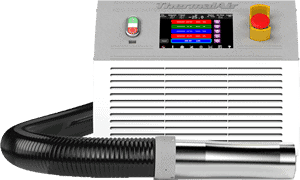

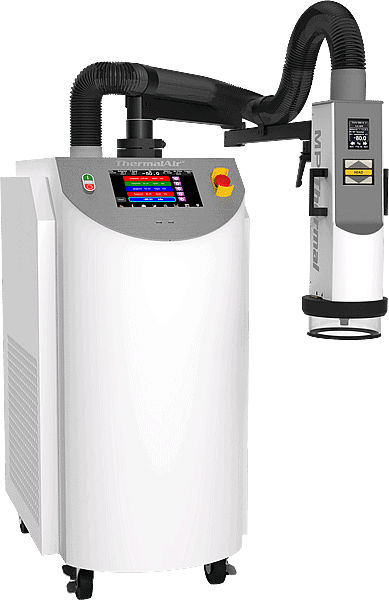

The ThermalAir Series of temperature systems brings precise thermal testing capabilities directly to your test application. In the test engineering lab or on the production test floor, the ThermalAir temperature system provide flexible test solutions for an array of products and technologies.

-100°C / +300°C

The ThermalAir Series of temperature systems brings precise thermal testing capabilities directly to your test application. In the test engineering lab or on the production test floor, the ThermalAir temperature system provide flexible test solutions for an array of products and technologies.

-100°C / +300°C

TA-5000A with Glass Cap

-80°C to +225°C

The ThermalAir TA-5000A delivers a precise thermal stream of hot or cold dry air -80°C to +225°C capabilities directly to your test application, exactly localizing to where thermal conditioning and temperature cycle is required.

Output Temperature Control

The ThermalAir TA-5000A can be controlled by user setting, the ramp rate, and temperature transition time as fast as -55°C to +125°C in less than 10 seconds. Users can control the flow rate from 4 to 25 SCFM.

How Does It Work

The TA-5000’s built-in air dryer and filtering system sends clean dry air stream (CDA) through its powerful internal chiller/heat exchanger to deliver hot & cold temperatures from -80°C to +225°C.

The ThermalAir temperature test system is all self-contained. You plug it in and it’s ready to start thermal testing your parts. (No configuration required.)

Performance Plus! - Productivity!

- Output Air Flow up to 25 SCFM from -80°C to +225°C

- -55°C to +125°C / +125°C to -55°C < 10 sec.

- Ultra-stable DC Temperature Control

- Frost-Free Operation / Heated Purge / Built-in Air Dryer

- No LN2 or CO2 / CFC Free / CE Mark

Features & Overview

Download the Datasheets

TA-5000A with Clamshell & Flex Hose

-80°C to +225°C

ThermalAir Clamshell Style Benchtop Environmental Test Compact Chamber is for temperature testing all types of components such as Automotive Parts, Sensors, Fiber Optic Transceivers, Microwave Devices, MCM, PCB, and all types of Electronic / Non-Electronic parts.

The Clamshell Compact Chamber can be opened and closed for quick and easy loading/unloading of parts that need temperature tests and thermal conditioning.

Users can test their electronic/non-electronic parts and other devices at temperatures from -60°C to +200°C with the Clamshell Style Chamber with precise temperature accuracy and uniformity, unmatched by large environmental temperature chambers.

Features & Overview

Download the Datasheets

TA-5000A with Hood Style Compact Chamber

-80°C to +225°C

ThermalAir TA-5000A Hood Style Compact Chamber is for temperature testing all types of components such as Automotive Parts, Sensors, Fiber Optic Transceivers, Microwave Devices, MCM, PCB, and all types of Electronic / Non-Electronic parts, and other test articles.

The Hood Style Compact Chamber is a thermal test enclosure that can be raised and lowered down over the unit under test for quick and easy loading/unloading of parts right on your test station bench.

Temperature test and cycle your test articles and devices, using the Hood Style Chamber at temperatures from -60° to +200°C. This chamber offers temperature accuracy and uniformity unmatched by standard environmental temperature test chambers.

Features & Overview

Download the Datasheets

TA-5000B with Clamshell Chamber & Flex Hose

-80°C to +225°C

ThermalAir Compact Environmental Test Chamber is for electronic tests at temperatures of all types of components such as Automotive Sensors, Fiber Optic SFP Transceivers, RF Microwave Devices, Hybrids, Semiconductors, MCM, PCB, or type Electronic Components / Non-Electronic parts.

The ThermalAir TA-5000B brings precise -80°C to +225°C thermal capabilities directly to your test application, exactly localizing where temperature testing is required.

ThermalAir TA-5000B Clamshell Test Chamber can be opened and closed for quick and easy loading/unloading of parts that need temperature testing and thermal conditioning.

Users can temperature test their electronic/non-electronic parts and other devices from -60°C to +200°C with the Clamshell Style Test Chamber at temperature accuracy and uniformity unmatched by large environmental test chambers.

Features & Overview

Download the Datasheets

TA-5000B with Flex Hose

-80°C to +225°C

TA-5000B with Flex Extender Air Transfer Hose provides maximum flexibility and reach, in the lab, on the benchtop, or in the production line. The standard length of Flex Hose is 2ft. - 6ft. (Customized lengths available) The unique architecture of the ThermalAir TA-5000 creates an unprecedented performance.

Features & Overview

Download the Datasheets

TA-3000A with Thermal Glass Cap

A smaller footprint ThermalAir System

-65°C to +225°C

The ThermalAir TA-3000A high-capacity thermal air stream system brings precise thermal capabilities directly to your test application, exactly localizing to where temperature testing is required. It is used for temperature testing, fast thermal cycling, and device temperature characterization of components, hybrids, modules, PCBs, and other electronic and non-electronic assemblies at precise temperatures from -65°C to +225°C.

ThermalAir TA-3000 Temperature Forcing System and Environmental Test Chambers are for temperature testing all types of components such as Automotive Sensors, Fiber Optic Components, Microwave Hybrids, MCM, PCB, or type Electronic Components / Non-Electronic parts, and other Test Articles.

Features & Overview

Download the Datasheets

TA-3000B with Flex Extender Hose

ThermalAir Thermal Cycling Test System

-65°C to +225°C

ThermalAir TA-3000B temperature forcing test system is super compact at 42 inches high and 20 inches wide. It is for hot and cold test temperatures down to -60°C testing with fast temperature transitions and fast ramp rates.

The TA-3000B is designed for testing all types of components such as Automotive Sensors, Fiber Optic Transceivers, Microwave RF Hybrids, MCM, PCB, or type Electronic Components / Non-Electronic parts, and other test articles.

This compact ThermalAir TA-3000B can be interfaced with any bench top temperature chamber whether users designed or designed by MPI Thermal. These thermal enclosures bring the temperatures closed to your UUT/DUT for quick and easy temperature test and thermal conditioning needs.

Features & Overview

Download the Datasheets

TA-1000A ThermalAir System

BenchTop Thermal Stream System

-25°C to +200°C

The ThermalAir Desktop TA-1000A System is the smallest in the product lineup for temperature testing of all components such as Sensors, Fiber Optic Transceivers & Components, Microwave Hybrids, MCM, PCB, or Electronic Devices/Non-Electronic parts. It operates within a precise temperature range from -25°C to +200°C, enabling fast thermal cycling and device temperature characterization.

With its compact desktop size, the ThermalAir TA-1000 can be conveniently placed on top or beneath the workstation test bench in the engineering lab or lined up on the production test floor. This system provides precise temperature control and is suitable for fulfilling your temperature test and thermal conditioning needs.

Features & Overview

Download the Datasheets

TA-1000B ThermalAir System

Rack Mount Thermal Stream System

-25°C to +200°C

The ThermalAir Desktop TA-1000B System is the smallest in the product lineup, ideal for temperature testing of all components such as Sensors, Fiber Optic Transceivers & Components, Microwave Hybrids, MCM, PCB, or Electronic Devices/Non-Electronic parts. It operates within a precise temperature range from -25°C to +200°C, enabling fast thermal cycling and device temperature characterization.

The ThermalAir TA-1000B, with its desktop size, is suitable for use within 19-inch server racks in the engineering lab or lined up on the production test floor. This system provides precise temperature control and is ideal for fulfilling your temperature test and thermal conditioning requirements.

Features & Overview

Download the Datasheets

TC-100 Ultra Cold Air Chiller

Cold Temperature Inducing System

Continuous -80°C Clean Dry Air @ 24 SCFM

The MPI ThermalAir TC-100 high-capacity thermal air process air chiller system is an alternative to LN2 and CO2. It is used for temperature testing and localized temperature-inducing continuous -80°C Clean Dry Air.

Replace LN2 and CO2 in many temperature test applications.

The unique architecture of the ThermalAir TC-100 Chiller creates unprecedented performance at the ultimate cold -80°C while saving up to 50% on electricity/energy/power!

Energy Efficient Ultra-stable Mechanical Refrigeration

- Built-in Air Drying System

- Alternative to LN2 or CO2

- Plug-in Anywhere Worldwide

- No Electrical Configuration Needed

Features & Overview

Download the Datasheets

- Product Line and Models Configuration Overview

The ThermalAir Series of temperature test systems brings precise thermal testing capabilities directly to your test application. In the test engineering lab or on the production test floor

MPI Thermal Product Line and

Models Configuration OverviewProduct

Thermal AccessoriesProduct

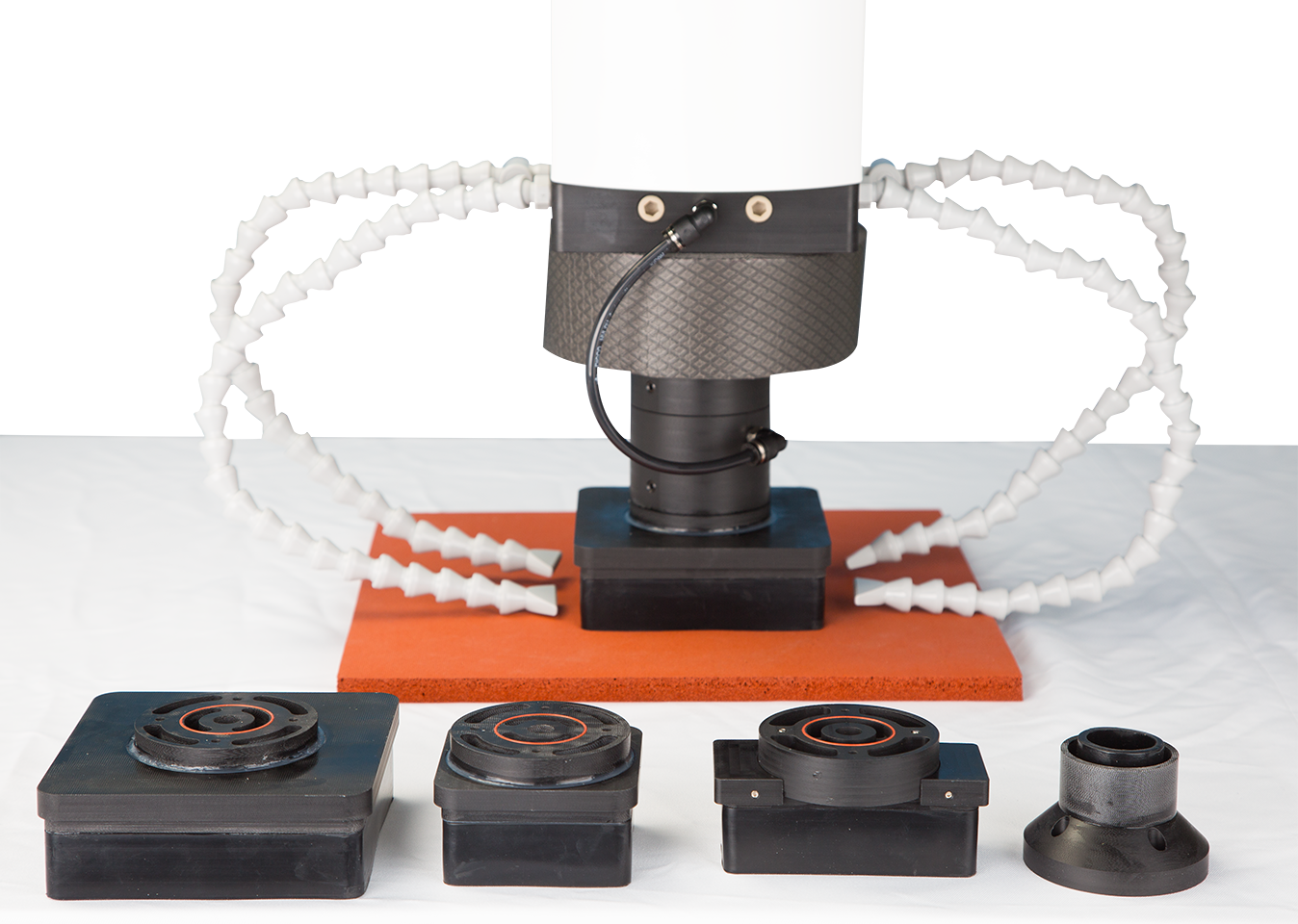

The ThermalAir accessories incorporate an intuitive full function for the ThermalAir users with the flexibility to accurately test in a variety of ways at the thermal test workstation.

MPI Thermal Accessories

Divisional Overview BrochuresProduct

MPI Thermal Divisional Overview & Product Overview

Take on a Tour of MPI Thermal's Products!

MPI Thermal Video LibraryVideos for the Full Product Line of the ThermalAir Series Equipment

MPI Thermal Video Library

Videos

MPI Thermal Temperature Test Solutions - New VideosMPI Thermal Temperature Test Solutions

Check out the ThermalAir Series Temperature Forcing Systems presentation videos. Discover how the Thermal technology brings temperature to your test workstation.

Videos

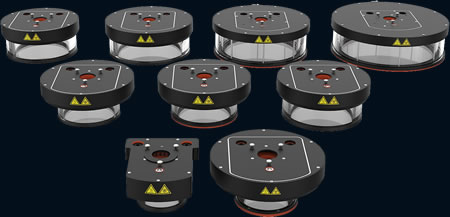

MPI Thermal Cycling Test ChambersProduct

Clamshell Style compact test chamber in standard and custom dimensions for many size devices and components in Aerospace, Semiconductor, RF Microwave, Automotive electronic, Fiber Optic Components..

MPI Thermal Cycling Test Chambers