MPI follows the GRI Standards to analyze the level of stakeholder concern and the operational impact of various issues. Through this process, we identify key material topics and establish management approaches and performance indicators accordingly. Material topics are deliberated by the ESG Task Force and reviewed by the ESG Committee to ensure that operational decisions at all stages are aligned with the company’s sustainable development objectives.

The 2024 implementation results of material topic and risk management were reported to the Board of Directors on August 13, 2025, where the Board approved the results and endorsed the continued advancement of follow-up measures. This strengthens MPI’s sustainability governance framework and enhances overall risk management effectiveness.

Understanding Organizational Context

Selection of Concerned Issues

In the initial assessment year, MPI conducted a comprehensive review of key issues of concern within domestic and international industries. These issues were consolidated and finalized as MPI’s sustainability development topics following deliberation and approval by the ESG Committee.

Determination of Stakeholder Groups and Communication Methods

MPI identified stakeholders with significant influence on the company’s operations and sustainability strategies. In the initial assessment year, stakeholder engagement on ESG-related topics primarily relied on proactive communications from stakeholders through various channels, including official correspondence, surveys, audits, on-site visits, telephone communications, meetings, opinion boxes, and dedicated email contacts, serving as the main channels for internal and external topic-related communication.

Identification of Actual and Potential Impacts

Identification and Analysis of Current Risk

ESG risk analysis was conducted on all departments in the year, and the risk level and operational impact of each issue of each year were determined based on the “likelihood” and “external impact” of risks.

Identification of Actual and Potential Impacts

Based on stakeholder concerns and by integrating both internal and external topics, MPI provides an assessment of the actual and potential positive and negative impacts associated with each material topic.

Assessment of Impact Significance

Analysis of Actual and Potential Impacts

The “operational impact” and “impact likelihood” were judged based on the results of ESG risk identification, the tension of issues that concerned stakeholders, and impact description, and the tension of concerned issues (general, high, prioritized) was determined.

Prioritization of Most Significant Impacts

Determining Priority Reporting Order

Determination of Material Topics

Based on the frequency and importance of issues raised by stakeholders, topics classified as “priority concerns” are identified and designated as MPI’s material topics.

Setting Management Approaches

For each material topic, management approaches are defined and implemented by the responsible departments to ensure effective execution and alignment with MPI’s sustainability objectives.

Selection of Concerned Issues and Material Topics

| Environmental | ||

|---|---|---|

| No. | Concerned Issue | Material Topic |

| 1 | Green Products | |

| 2 | Environmental Energy | V |

| 3 | Greenhouse Gases | V |

| 4 | Biodiversity | |

| 5 | Climate Change | |

| Social | ||

|---|---|---|

| No. | Concerned Issue | Material Topic |

| 6 | Labor and Human Rights | |

| 7 | Employee Development | |

| 8 | Occupational Safety | V |

| 9 | Workplace Welfare | V |

| 10 | Social Responsibility | |

| 11 | Product Responsibility | V |

| Governance | ||

|---|---|---|

| No. | Concerned Issue | Material Topic |

| 12 | Quality Management | V |

| 13 | Corporate Governance | |

| 14 | Ethical Integrity | |

| 15 | Business Performance | V |

| 16 | Regulatory Compliance | V |

| 17 | BCM | V |

| 18 | Supply Chain Management | V |

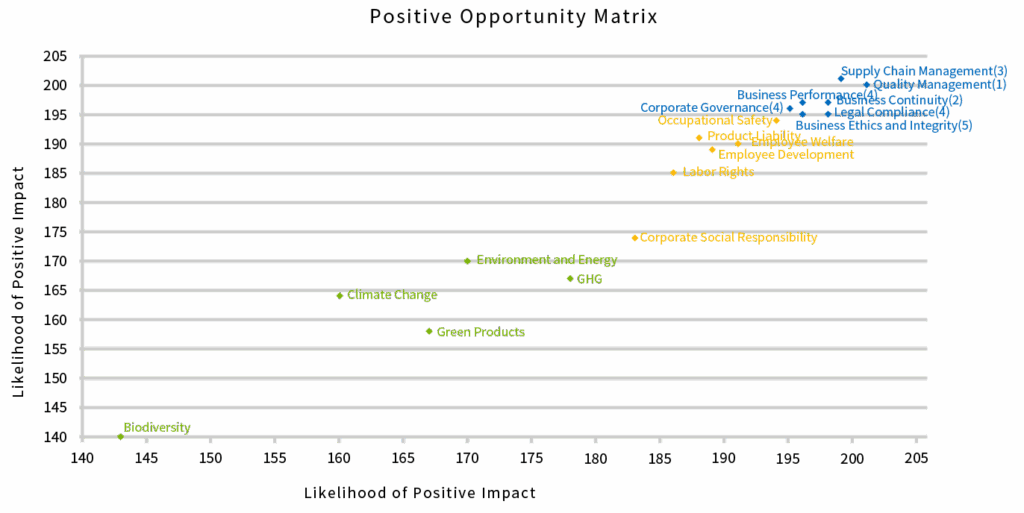

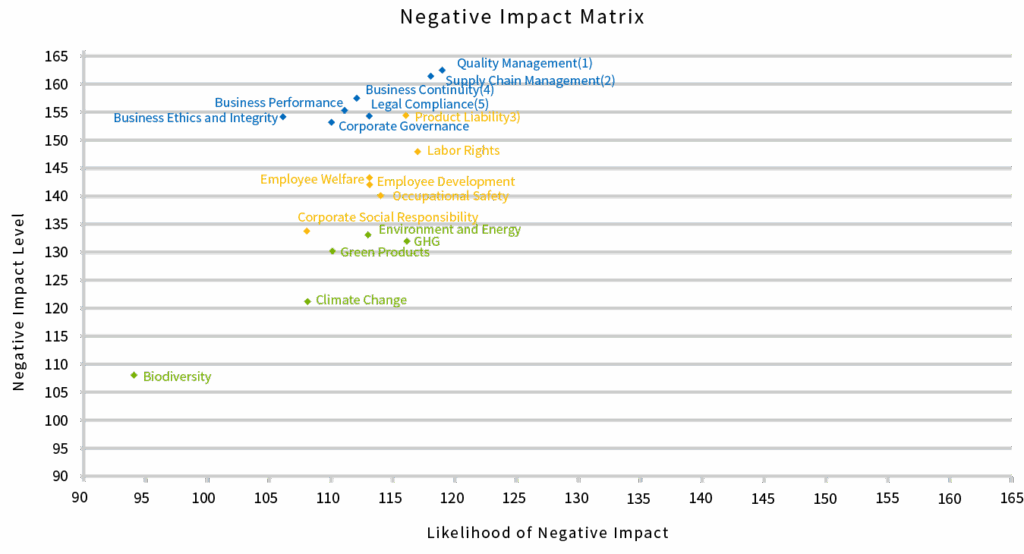

Positive and Negative Impact Matrix

Positive Opportunity Matrix

Negative Impact Matrix

| Material Topic | Management Approach | Management Objectives | 2024 Implementation Results |

|---|---|---|---|

| Green Products | Continue to develop products that meet sustainable and green market demands | Maintain R&D investment at 5–10% of annual revenue | Specific products obtained CE, NRTL, UKCA, and RoHS certifications |

| Closely monitored emerging technology trends | Provide customized products tailored to customer needs | ||

| Business Performance | Offer comprehensive test application solutions and test interface products | Continuous global deployment of distributors, dealers, and business partnerships | R&D expenses totaled NT$1,089,293 thousand in 2024, representing 10.71% of revenue |

| Global market deployment to reduce operational risk | Maintain steady revenue growth and profitability | ||

| GHG | Implement phased GHG inventory and verification across the Group | The parent company continues to complete verification work | Completed the third year of GHG inventory and verification |

| Set short, medium, and long-term carbon reduction targets | Plan phased introduction and verification for subsidiaries | ||

| Occupational Safety | Improve the occupational safety environment beyond legal and regulatory requirements | Disabling injury incident due to occupational accident: 0 | No incidents of disabling injuries, major legal violations, or occupational diseases caused by chemical exposure occurred |

| Comply with the Occupational Safety and Health Management System standards | Material legal non-compliance incident (fine over NT$1 million): 0 cases | Completion rate of annual employee health checkup: 100% | |

| Work-related ill health due to chemical exposure: 0 | |||

| Completion rate of annual employee health checkup: 100% | |||

| Quality Management | The quality objective is to enhance customer competitiveness with superior products, excellent service, and regulatory compliance | Target project completion rate: 95% | Project completion rate: 97.75% (VPC) |

| Target customer service satisfaction rate: 85% | Actual customer satisfaction rate: 90 (PC) | ||

| Business Continuity | Conduct ongoing risk assessments and implement continuous improvements | Introduction of ISO 22301 system | Obtained 3rd Party Management System Verification |

| Gradually adopt and integrate the Business Continuity Management System (BCMS) standards | Phased completion of verification across business groups | ||

| Supply Chain Management | Continuously strengthen supply chain quality, social, and environmental management | Key suppliers who have signed prohibition of hazardous substances and conflict minerals agreements: 70% | 83% of key suppliers signed the “No Use of Conflict Minerals” declaration |

| Ensure supply chain resilience and operational visibility | Rate of signing of the Integrity and Non-Corruption Agreement by qualified suppliers: 80% | 89% of key suppliers signed the “Restricted and Prohibited Substances” declaration | |

| Progressively complete RBA (Responsible Business Alliance) declarations and audit verifications for critical suppliers | RBA-CoC investigations or audits | 67% signed the Integrity and Non-Corruption Agreement | |

| Product Liability | Listed as a material topic starting from 2025 | Achieve an average satisfaction score of 85 points for designated key customers | Met customer requirements with no major product liability incidents reported |

| Manage product anomaly rates and days of deviation according to BU-specific quality management rules | |||

| Obtain international certifications such as CE, NRTL, and UKCA for designated products | |||

| Employee Welfare | Enhance remuneration structures to maintain market competitiveness | Employee remuneration complies with laws and regulations, and the median salary is higher than the industry average | 2024 Median Salary (MPI rank / publicly listed semiconductor companies: 23/99) |

| Foster an open, respectful, diverse, and supportive workplace to improve employee satisfaction | Average employee satisfaction score: 9.3 out of 10 | Employee satisfaction score: 9.33 out of 10 | |

| Legal Compliance | Listed as a material topic starting from 2025 | Material legal violations (over NT$1 million): < 1 incident | Zero cases of material regulatory violations 100% corrective action completion rate for all identified non-compliance issues from regulatory audits |

| 100% corrective action completion rate for all identified non-compliance issues from regulatory audits |