In the global semiconductor supply chain, Taiwan plays a critical role as a hub for contract manufacturing and testing services. Given the increasing risks posed by extreme weather events, supply chain disruptions, regional conflicts, and other potential emergencies, MPI places operational resilience at the core of its long-term strategic planning. The Company focuses on minimizing the impact of disruptions and ensuring the ability to recover swiftly, thereby protecting business continuity and sustaining customer trust.

On January 6, 2025, MPI successfully obtained its first ISO 22301 Business Continuity Management System (BCMS) certification, demonstrating its robust operational resilience and capability to manage business risks. Through proactive risk identification, impact assessment, and response planning, MPI strengthens its capacity to anticipate and mitigate potential disruptions, minimizing unexpected impacts and safeguarding long-term customer relationships.

Business Continuity Policy and Objectives

Policy

- Strive to become a leading provider of test solution design and manufacturing, delivering exceptional and uninterrupted services to customers.

- Implement robust business continuity management procedures and allocate appropriate resources to ensure the ongoing effectiveness of management systems.

- Enhance resilience in responding to major disasters and unexpected events, reducing the risks and impacts of operational disruptions while safeguarding customer competitiveness and pursuing sustainable growth.

Objectives

- Reduce the risk of operational disruptions for customers.

- Reduce the risk of supply chain disruptions.

- Ensure the effective operation of the Business Continuity Management System (BCMS).

- Prevent potential operational disruptions caused by major incidents.

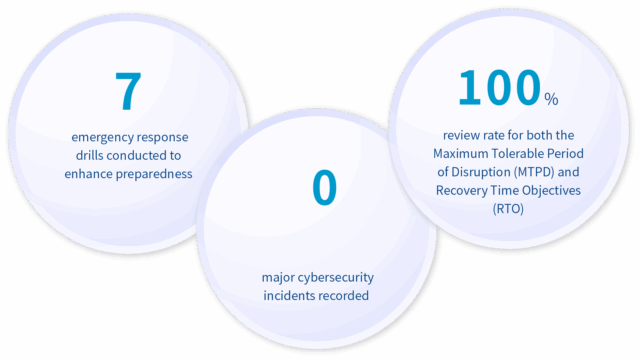

2024 Key Business Continuity Management Indicators